Marinero – 6

*Melt coating production Jürgen Leßlhumer from Wood K Plus wrote a summary based on interview questions: Can you explain what exact materials are used to create the sample 1 textured filament? For the production of the textured filament we used a high viscosity polyamide 6 …

Fragments Garments #7 – Co-creation residency in Hub Linz (Part 3)

Clothing Fasteners 3D Printing As the entire project revolves around local and on-demand production of customizable seamless and modular garments, I decided to enrich the offer to the consumer with personalized clothing fasteners using 3D printing technologies and micro-nebulization dyeing. SLA Printed Fastener The first …

Fragments Garments #6 – Co-creation residency in Hub Linz (Part 2)

Modeling Foot Arch for 3D Printed Shoes Now that the shoe high heels were prototyped, I needed to adapt them perfectly to the foot arch. To do so, I needed a precise 3D model of what we call a “shoe form”, i.e. a plastic made …

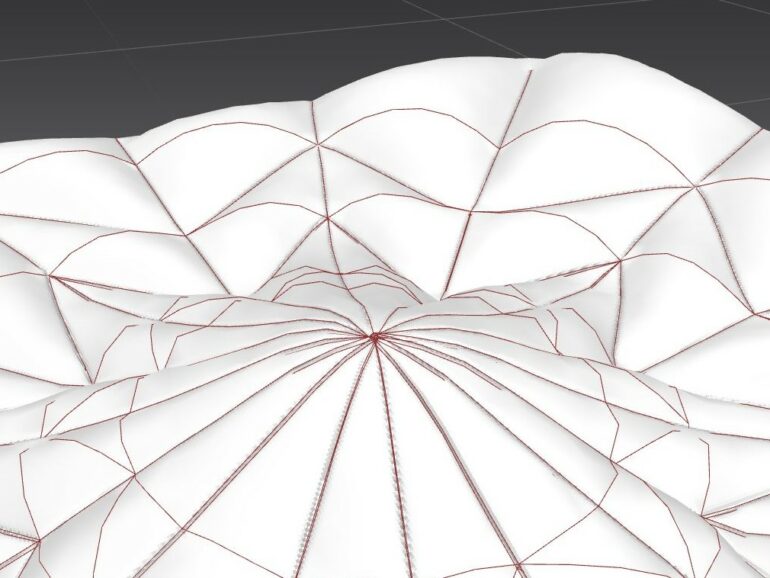

Virtual prototyping

We are finally back in Fraunhofer IZM since a couple of weeks, after a long break due to the infamous pandemic. Useless to mention that the last few months have been challenging since the co-creation process involved members of our team visiting labs for material …

Fragments Garments #5 – Co-creation residency in Hub Linz (Part 1)

Residency Objectives Develop an articulated and customizable 3D printed high heels pair of shoes combining soft and hard printing materials. Develop 3D printed customizable and reusable clothing fasteners, to be produced on-demand, to be then dyed using the micro-nebulization process of Care Applications. As my …

Fragments Garments #9 – Material Sourcing & Sampling Tests

Sustainable Fabric Sourcing For each of my projects, I usually source fabrics locally. As my main partners were in Alcoi, I decided to scout fabric suppliers in Spain. I had the chance to get help from Blanca Gomara from B2Fabric which is a specialist in …

Fragments Garments #8 – Covid-19 Seamless Facial Protection Masks

Facing an Unprecedented Event Like all artists, designers, scientists, and technicians from the Re-Fream crew, I have been deeply impacted by the consequences of the Covid-19 crisis. As explained in my previous post, I was in a co-creation residency in Austria when the government decided …

Fashion Design and Reverse Engineering? – Conversation with Guillaume, Sander and Ganit

As part of my research within ReFREAM project, I interviewed Guillaume (Haratech) and Sander (F&T) about the idea of using 3D scanning in the context of fashion design. They were both part of the process I worked on in Linz, Austria, in which I scanned …

APeel-New Collection

Our design brings revolutionary concepts into reality, a perfect combination of technology and aesthetics, products featuring circular design and sustainability. Focusing on one of the key factors in our design, sustainability, we introduce our independent-developed material ‘APeel’. APeel is a bio-material that utilises the seemingly …

Bio-Material Innovation

In the field of textile and material industry, innovation never comes easy. Being a new-material researcher and fashion designer, my mindset has shifted as I am not just designing products but forming an eco-system around my product, establishing a viable solution to sustainable fashion and …