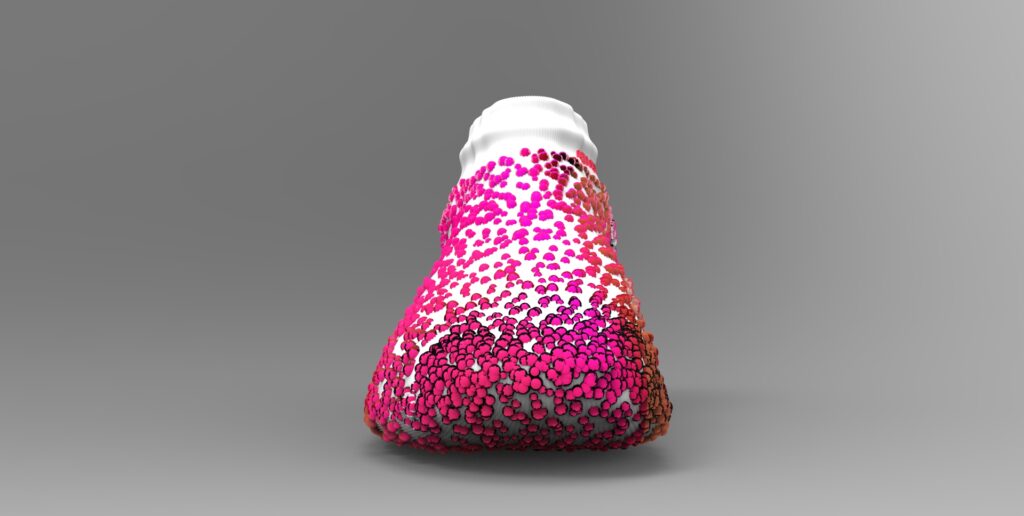

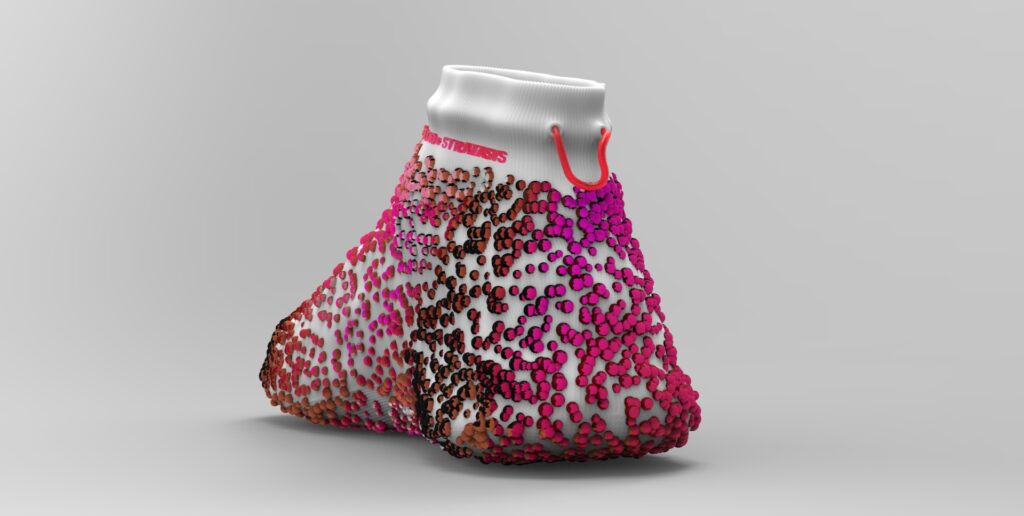

The ‘Sepida’ shoe is 3D printed on fabric with a ‘slide in’ evolutionary personalised midsole – Assa Ashuach

The Sepida shoes are part of the ‘Evolve IM’, a new biometric evolutionary footwear.

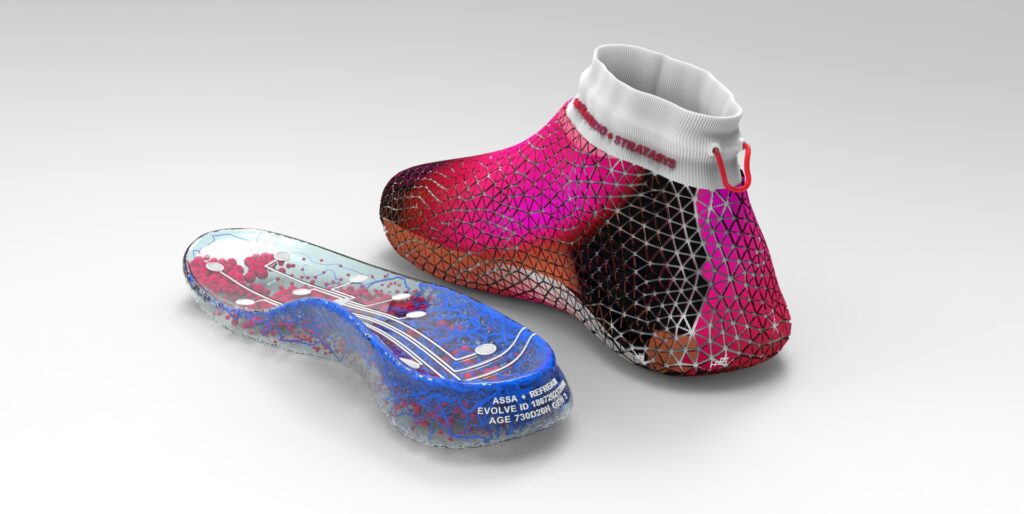

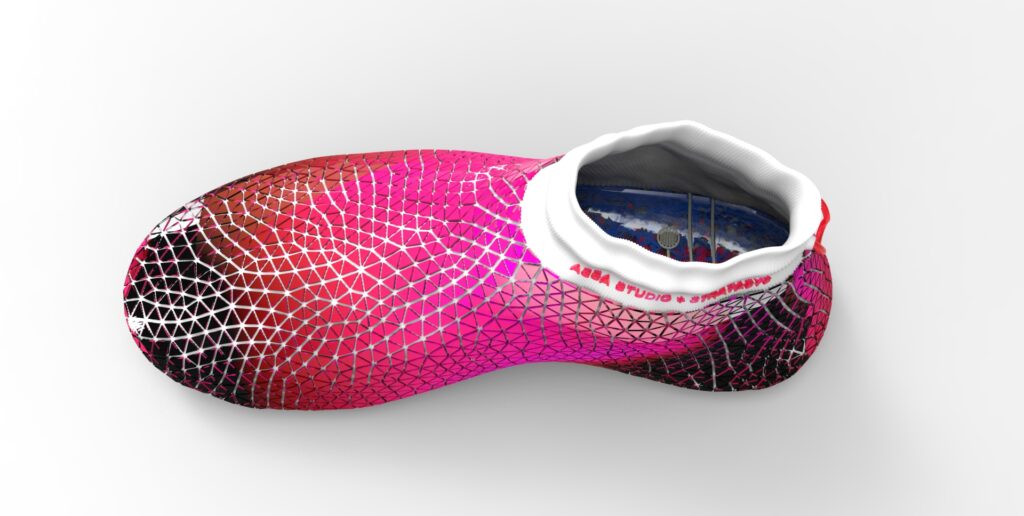

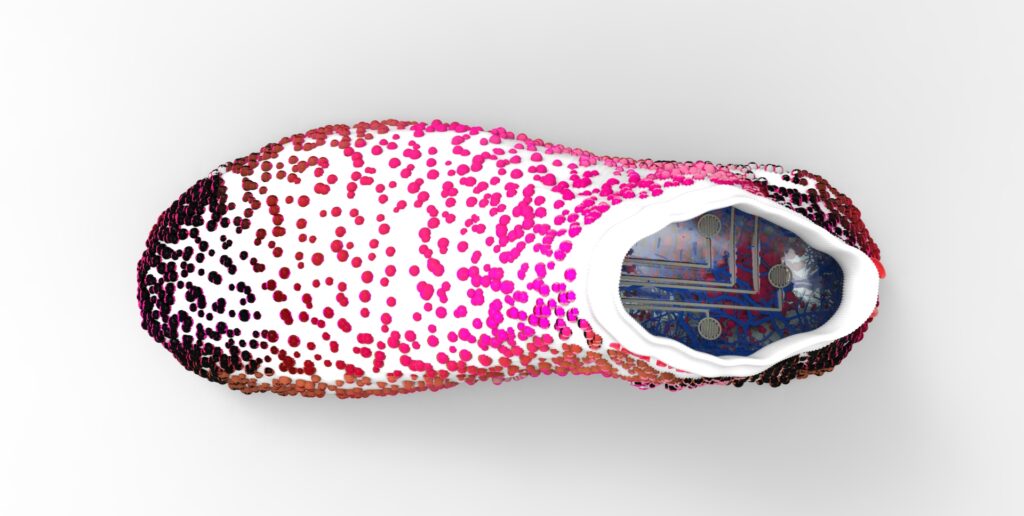

In this project, we worked on three main domains: evolutionary design, circular design, and 3D printing on fabric footwear. This post focuses on 3D printing on fabric. The Spedia shoe design and manufacturing processes propose a new methodology, whereby a 3D printer deposits an array of different materials on a designed fabric pattern at different thicknesses, shapes, and characteristics to enhance overall performance and personal fit of the shoe. In this case, we have designed a ‘sock’ like shoe exterior around a midsole interior part. This has allowed for multiple socks designs to fit over the one personalised evolutionary midsole. It means that a user can keep their one evolutionary midsole for a longer period, and replace the outer sock if needed. One evolutionary midsole can come with several outer sock designs, for example, one for running, and another for normal urban daily life etc…

A shoe that studies its user and improves over time. We propose a new evolutionary design approach, whereby user sensors biometric data is collected over time, to achieve a gradual improvement of the shoe. Users simply live their lives, while the object virtually evolves and improves over time.

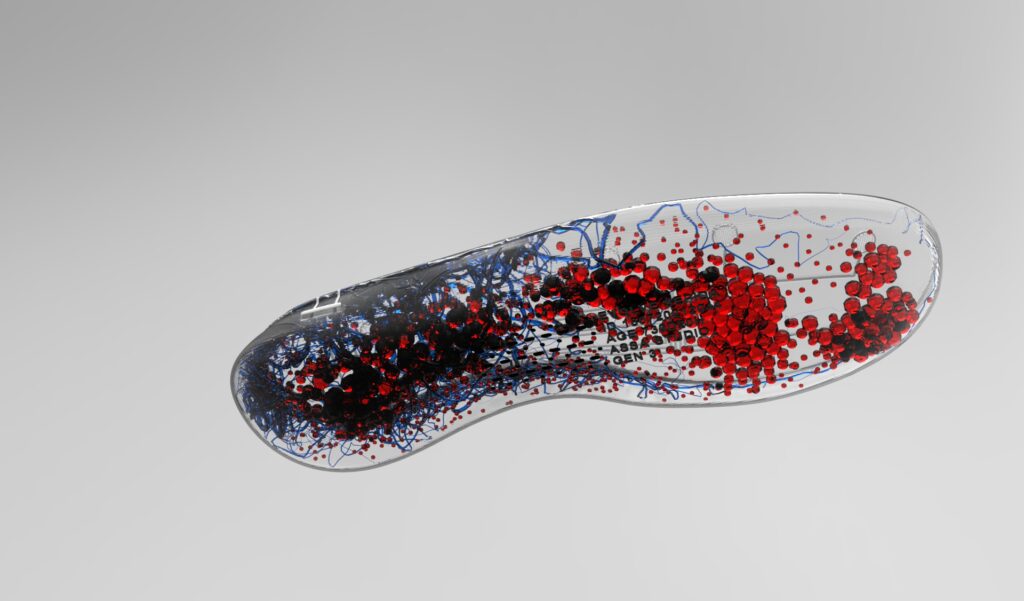

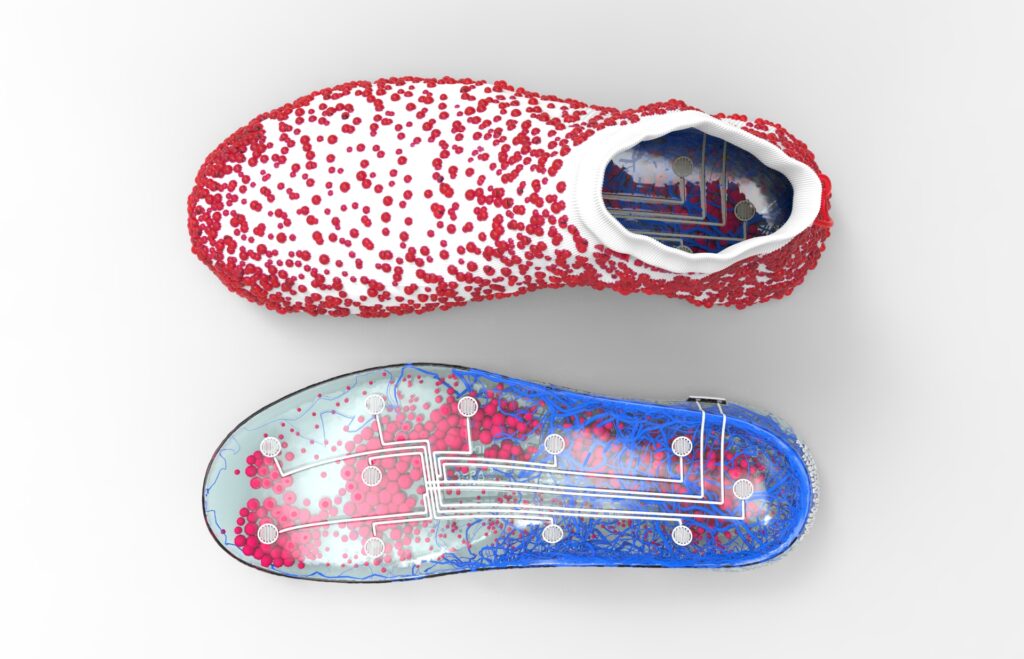

This project proposes to use the existing 3D scanning and biometric sensor readings technologies to hybrid manufacture footwear tailored to the user’s way of walking, ergonomics, and foot weight distribution. We embed biometric sensors in first-generation shoes to collect individual users’ data to improve their next-generation shoes. It is about adding the element of TIME to the design process, using computational power IoT, M2M, and machine learning. We have 3D printed the pressure sensor electronics with a novel combination of chemistry by our partners Profactor in Austria and Stratasys in Israel.

Innovations in personal fit.

In collaboration with the Stratasys Polyjet technology R&D team, we have been using a new CMF approach to multi-material, colour and density, using an array of liquid gels and rubber tissues varieties. Based upon the embedded footwear pressure, heat and humidity sensor matrix within the midsole and upperparts, we can now autonomously generate the optimal combination of soft gel particles and bespoke support structures around the user’s foot, to achieve the best cushioning, heel support and upper ventilation possible.

Planet

I believe that by adding personal value we increase the object perceived value, and by that, consume less. I propose a new digital sustainable ecosystem that reduces materials, production energy, storage, transportation and overall carbon emissions down to the bare essentials. A new brand user connection is established, leading to an emotional connection with an object that evolves, based upon the user’s essential data and way of living. We are making the objects life far longer, by evolving it to become better to both user ergonomics, and its geographical terrain and climate. The Evolve collection is designed to be manufactured using a network of decentralised AM machines and new local assembly paradigms with the potential for urban micro economy regeneration and stimulation.