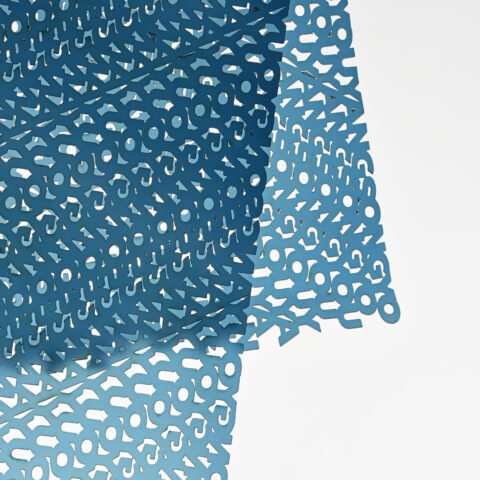

Inspired by fruit flavors, textile designer Youyang Song developed a fully biodegradable leather by simmering orange and banana peels. The resulting PEELSPHERE fabric offers an alternative to animal skins and their toxic tannery treatments, while also transforming food waste. Her Re-FREAM co-creation process explored cutting-edge manufacturing options for the material, such as computer-aided laser cutting, paving the way for future products ranging from fashion to vases and textured lamp shades.

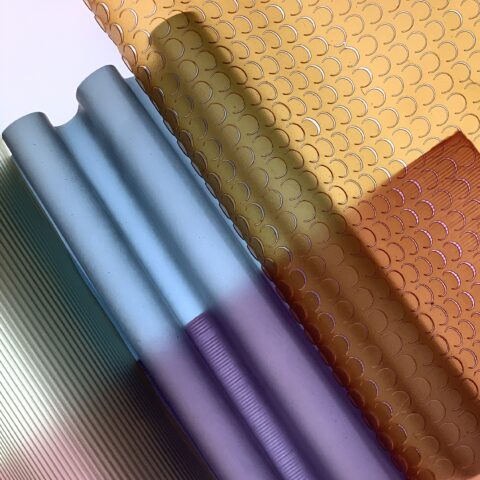

PEELSPHERE is as robust, flexible and smoot as leather – yet lets light pass through, like a stained-glass window. It unrolls languidly, as if aware of its translucent allure. “You can see the fibers inside”, Song explains its texture, “not every banana can be the same, so every piece of material is unique”. The composite is fully biodegradable and fully circular: it can be reused through re-manufacturing. Apart from molding different patterns, the zero waste product’s manufacturing potentials remained to be explored – which was accomplished through the co-creation. The applications and adaptations of existing machinery to bio-cellulose material has wide implications for the textile industry, ranging from garments to healthcare and cosmetics to furnishings.

Key to Song’s Re-FREAM co-creation is not merely conserving the environment but helping to restore it. Beyond the circular loop, this entails sustainable design not at the expense of aesthetics, but consciously embedding aesthetic pleasure and joy. Materials are designed for their experience and perception. While these wearable bananas are a far cry from Josephine Baker’s costumes, they do convey a different joy: one of serene contemplation. Whether transformed into bags or vases, in lace patterns or grids, each hue and form of the bioleather emanates a satisfying, radiant stillness. Manufacturing sustainable products becomes about savoring beauty in complete respect for the environment.

“The exchanges with Aitex taught me a lot about the material – including the antibacterial performance, and necessary manufacturing requirements to take production to scale”, says Song. Exchanges with other Re-FREAM artists working on materials – especially Fabio Molinas and Jef Montes – also yielded new approaches. As textile designer, she has faced the challenges of exploring biological compositions and their properties, while aiming to optimize the material to best achieve outstanding performance. Songs’ circular concept has garnered wide attention and have been exhibited at MUNICH FABRIC START and the ZKM | Center for Art and Media in Germany, at the ARS ELECTRONICA Exhibition in China, Austria, the Salone Del Mobile in Italy, as well as the Dutch Design Week.

Beyond the material, Song would like to scale the entire production process holistically, ranging from the systematic procurement of fruit waste and the manufacturing at scale to the distribution and marketing. A key element is local supplies of high-quality fruit waste or raw materials to reduce unnecessary transportation energy, another is redirecting the heat from manufacturing the substrate to the drying processes. Her business plan is ready – with investors on board, she then aims to bring the product to the market and broadening the team.

The Project

Cooking new materials is an independently developed technique which aims to process biowastes into a soft but yet robust leather-like material. Banana and orange peel or soy-milk are combined with a natural binding agent as the substrate.

The resulting composite is fully biodegradable and can be easily reused after the re-cooking process. It is a 100% biodegradable, zero waste natural product. Moreover, the bio-material provides similar toughness, durability and water resistance as normal leather material.

The Partners

Youyang Song is based in Berlin, and worked within the Sustainable Finishing Hub of Re-FREAM. She explored laser-cutting options with the Re-FREAM partner Aitex.

The Technologies

PEELSPHERE is a bio-innovated circular material made from fruit waste and algae through advanced material engineering. It is created by redefining fruit waste, reducing carbon footprint and designing for circularity. As an ideal alternative to leather and synthetic leather, the material is beautiful, durable, versatile with unparalleled performance and functionality. while reducing carbon footprints.

As a 100% biodegradable sustainable new material, PEELSPHERE born at the intersectionality of design, material science and sustainability, with recycling, redesign, and reuse, it is harnessed to enable a toxic-free, eco-friendly manufacturing process, with a mission to inspire a sustainable, healthy and balanced lifestyle through its quality and beauty.

Óscar Calvo, Aitex, about the project

“Youyang Song aims to revolutionize biomaterials with her special recipe for Cooking new materials. The co-creation experience at Aitex enabled technical improvements to upgrade both the manufacturing process as well as the material properties. Youyang brought to Aitex a very special material, made in an artisanal way, and needed to optimize in the process as well as the main properties, such as water and bacteria resistance.

She had to learn that research requires time and patience, as not every trial is successful at the first time. Then she was able to enjoy the co-research with the technicians. The Aitex team worked hand in hand with her for the necessary improvements towards new urban manufacturing possibilities.”

The Artist

“Before I entered the material industry I studied as a fashion design student. I learned and applied a lot of past experiences of fashion design into my current work, letting my material not only possess the features such as versatility, practicability and environment-friendly but also fully of artistic insights and emotion of beauty. This kind of cross-nation and intercultural experience allows me to make more unique and products.

- Bioyarn, inspired from molecular cooking, extract alginate from algae and obtain bio-degradable bioyarn through 3D-printing and needling.

- Schaum inseln, in order to solve the problem of shortage of public seating on alexanderplatz Berlin, I collect some of left-over foam of the Berlin Schaum company. Through 3D-printing and heat treatment, I turn damaged and rough surface of the foam into smooth, skin-friendly and apply a rather fashion design into them. Through interesting deconstructing, Montaging and bonding, I created mobile seats that can be assemble and dissembled freely.

- interactive hair band. I designed an interactive hair band, the hair band have six balls on it which represents six different musical notes. By installing conductive fibres onto the hair band rhythms can be played by tapping of those balls that generate corresponding sounds”

Follow YouYang

Blog Posts

Sustainable Design-Circular Economy

In project cooking new materials, one of the top priorities that we follow in our entire concept is sustainability and circular economy. While most industries are currently following a linear production model to meet the growth of market demand, our …