Cooking New Materials

Material that change the future?

Let’s face the fact, with this world of technological advancement, there has and will always be different sorts of innovations that claim they can change the future. However, what comes to me in the first place is creativity, power of the mind, how can I combine imagination with my understanding of techniques and care for the environment.

“Imagination is more important than knowledge. For knowledge is limited, whereas imagination embraces the entire world, stimulating progress, giving birth to evolution.”— Albert Einstein. Creativity and imagination might be some simple words to say, but looking into the deep meaning behind them, you will find out how complicate imagination and creating can be.

Plastic or leather materials nowadays use synthetic petrochemicals to be manufactured, due to the fact that they are easy and low cost to produce as well as they provide satisfying performance. However, we all know that we give up the environment for conveniences and profits. Manufacturing, recycling or disposing of those synthetic materials can cause extreme harm to the earth we live on, causing damage to lives and properties.

In recent years, with ever-increasing negative impacts of pollution and the pressure of waste management, environment-friendly material has become an urgent need to be developed. The sustainable approach of the material industry is to be expected when everyone is thinking of creating a kind of true harm-free material that is sustainable.

The idea of “Cooking New Material” comes to me during my master studies, when I was researching the origins of plastics and polymer compounds. I learned the fact that ancient civilization manufactures organic polymers using shellac and milk. I couldn’t help myself thinking how can I substitute those organic raw materials with our everyday bio-products.

Every time after enjoy the fruit, I was always thinking about conserving the fruitiness smell and develop a material based on fruit bio-waste that has the smell of fruits, refined texture and feels good on touch.

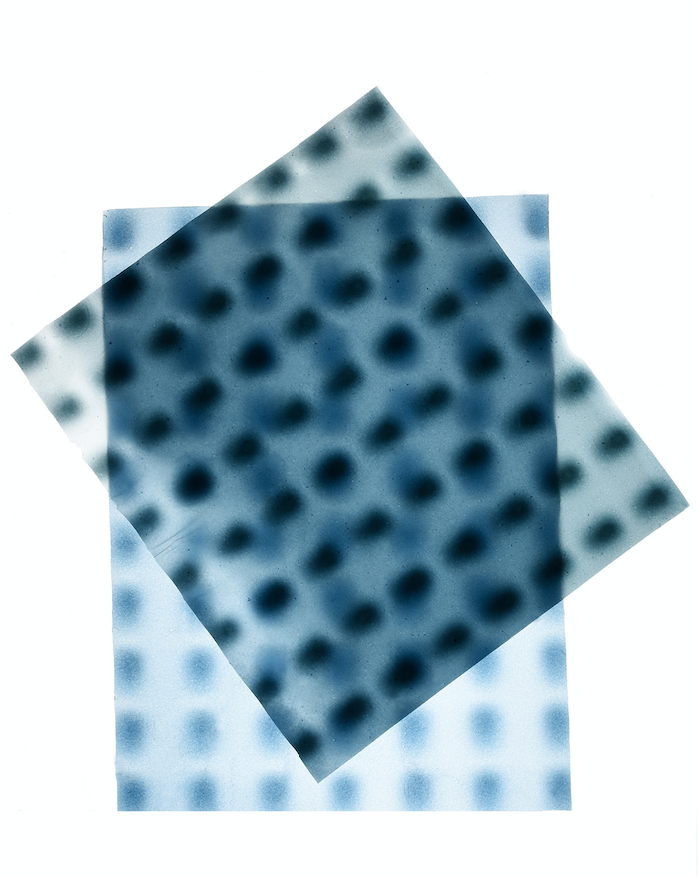

Colour extracted from indigo

After that I did some investigation about the amount of bio-waste generated in Berlin each year. There was approximately sixty thousand to seventy thousand tons of bio-waste produced in 2017 and roughly 17% of them are fruit wastes.

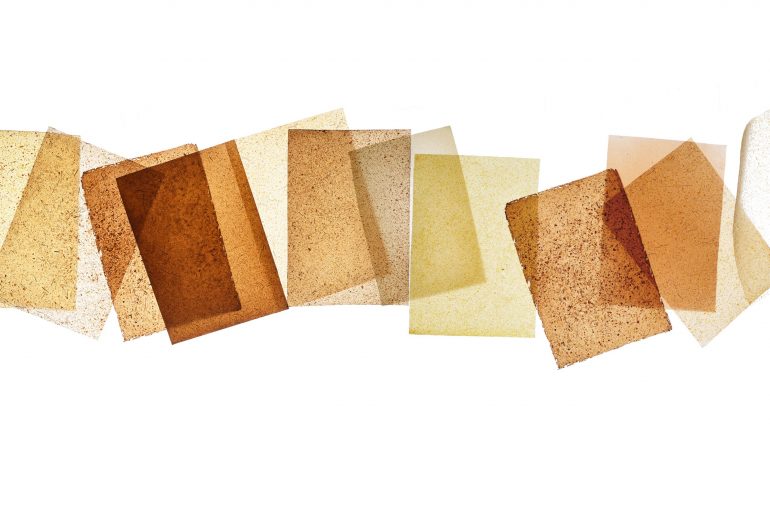

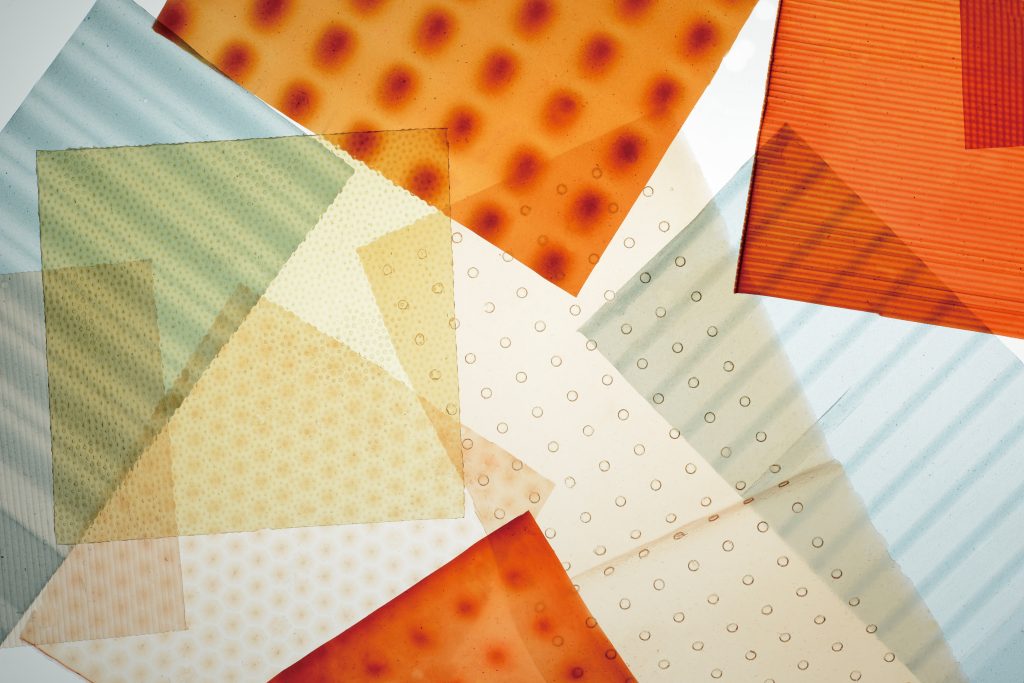

During the first few tryouts; the results are rather unsatisfying. But, giving up never appeared to me as I kept trying and testing, try to improve the formula and came up with prototypes I can work with. During this period of time, I also tried to add bio-coloring to the mixture to create my own collection with different patterns and colors.

During this entire time of experiments and attempts to improve the original formula, I always try to use bio-based material as well as food waste in order to keep the product as bio as possible. The reason behind this is not only for the material itself to be biodegradable but also for the sake of sustainability which I ultimately pursue.

During those years when I worked as a fashion designer, the use of bio-material or sustainable material has always been a trend for everybody. However, when I did my researches about sustainability, I realized that sustainability cannot be defined as simply using bio or sustainable material. As a fashion designer and material researcher, I will have to focus on a bigger picture. The real sustainability of material is a whole system with many pieces put together rather than a single element.

After a closer look at my sample and the capability of it being re-cooked and re-manufactured, the idea of creating an entire eco-system based on my material came up in my mind. In my concept, the material will be conserved in a closed cycle. The material is manufactured which then goes into the hands of the customers. When the product is broken or needs to be replaced, they will be collected from our customers and we will be able to fully recycle it. The recycling process should not create any waste of material since all of them are conserved within the closed system. Moreover, the material is completely safe to dispose of without inflicting any harm to the ecosystem. With this aim and guideline in mind, I start to work around a sustainable system around my material and try to conceptualize and refine each and every step of the recycle-remanufacture system.

I was very excited when my project was announced as one of the winning projects of RE-Fream, where I can finally get the chance to improve my material systematically and work on the closed system by the realization of the mass production capabilities. With access to different manufacturing and processing techniques such as laser cutting and 3D printing, I will be able to expand my product range and make the collection vibrant and aesthetic. As a designer, one of my priorities is always to appreciate the beauty and power of design. I will make sure that all of my products are filled with new ideas and possibilities during my constant research of combining aesthetics with functionality elegantly.

All in one, I look forward to the collaboration with Re-Fream and AITEX with their professionals. I believe with their knowledge of science, our passion for material science and pursuit of environment continuity we are one step closer to making this project a success.