LEATHER FOR VEGETARIANS TURNS INTO LEBIU

7 months ago, when I began this adventure that is the Re-Fream project, I would never have thought that throughout the development of the project, I could discover many different fields of application and production techniques using cork particles.

It seems yesterday when I saw the horizon of the project still far away, technical difficulties, logistics problems, and all the setbacks that always await you around the corner to put even more restrictions on its implementation.

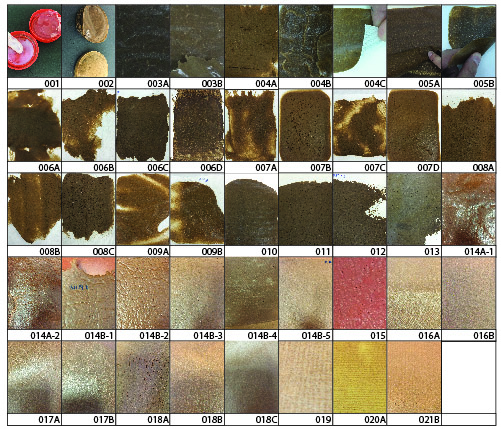

Test results during co-creation processHowever, the small mishaps that occurred along the way, helped me to get to know in-depth all the mechanical characteristics of cork and learn how to treat it, to transform it into something tangible, see in front of my eyes, what I had been envisioning since 8 years ago.

I don’t hide from you that in my trajectory throughout the project it has not been easy. Daily trial and error for almost 3 months, one day with positive results, another day starting again from the beginning. Thanks to this experience, I am understanding that there is no need to be in a hurry in such projects like this, knowing how to manage time is the key in every innovation project, what seemed wasteful to me at that time, helped me to understand how to mold such a difficult material (for its density, its hydrorepelence, and its peculiar structure that keeps the air inside its cells) and transforms it into what I wanted.

Testing, testing, testing....It is a long process, but I firmly believe that the designer has to be present in each and every phase so that he can give solutions, understand where something is wrong, and propose changes. At all times the designer has to ask himself questions, change his mind, improve it, refine it until he sees that the technical difficulties are less and more controllable.

This attitude is helping me to cover various fields of the project related to patents, creation of the Start-up, deciding with whom I will collaborate in phase two, and how I am going to present the final products to the world.

So in the part of developing the product I have also been designing the brand identity, trying to make visible what I wanted to express, the business plan, which is the key to any type of business, and the strategy I want to use to enter the textile market.

Lebiu BrandingWith all these milestones almost achieved, the Leather for vegetarians project became LEBIU (which means Lightness in Sardinian language), a design company that will produce, three types of products from cork waste.

CorSkin: A Bio-skin made from cork waste keeps the aesthetic appearance of real leather. With its percentage of cork powder plus bio-based additives, we provide a sustainable, animal-friendly coating for plenty of applications.

Neobuck: (Neo-Nubuck) is a new vegetal suede made from cork waste, it imitates the suede texture but totally made out of bioresources. Thanks to the consistency of the cork particles and the effect that the latest technology gives to the surface of the fabric, this new type of biomaterial can be used alone, or as a back part of the Corskin. No other synthetic leather on the market has such characteristic since the fabric is usually seen in the back.

NanoCork: it is a natural finish that can be applied to garments, using the minimum amount of water and chemical products as less as possible, proposing a new type of much more sustainable and ad HOC finishing process, where is produced only what is needed, without overproduction. The mist of cork particle penetrates in the fibers improving its resistance and giving a Bio-Denim effect.

The three materials can be combined to give new styles and applications in fashion products and objects.

CorSkin is the highest quality material from the Lebiu brand, having the characteristic of resembling real skin. Due to the optical effect that the particles make on the coating and the spongy nubuck effect of the bottom part make CorSkin the perfect material for shoes and accessories, without having to sew an internal cover to hide the back of the material. Neobuck has the same spongy finish, which can also be used as a garment.

Nanocork’s nebulization service will allow brands to customize their garments with the BioDenim effect and correct defects in the fabric, giving it a new life and avoiding waste of clothes and fabrics that have not passed the quality check due to aesthetic defects.

The idea is to be constantly evolving, integrating designers and collaborations so that each designer, manufacturer, the brands can experiment with the various finishes and create new applications.

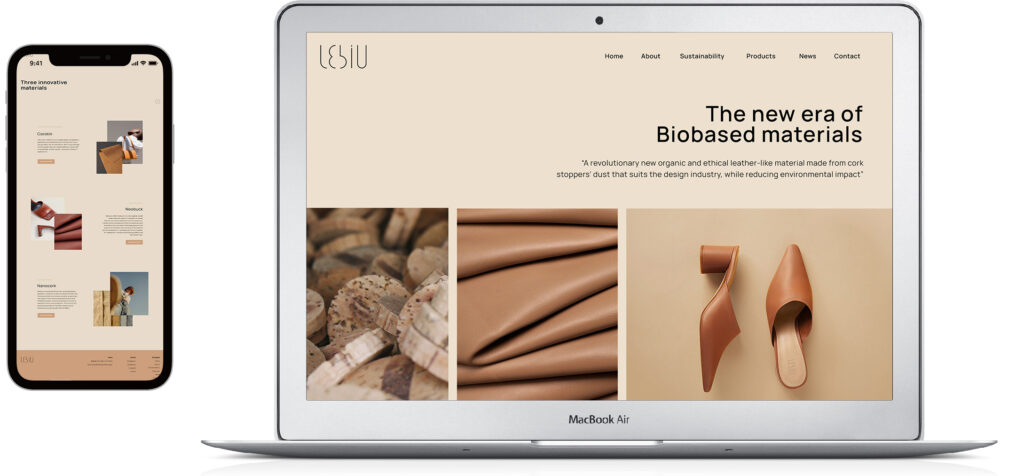

Lebiu website (mockup) At the same time, the website is being designed, which will present the characteristics of the materials, their level of sustainability, a part of the collaboration with micro-companies and designers, and a section of posts about sustainability with practical examples to educate the user about the environmental crisis.

There is still a long way to go, but “Slow and steady wins the race”.

website mockup