Keep It Together: Testing and Tryout for Seaming Solution – Yokai Studios

Trial and Error

Testing and Tryout for Seaming Solution

In our previous blog post we set up the criteria and settled on a range of common materials for the Zwick and Martindale testing.

As a brief reminder: the aim of these tryouts was to come closer to our goal of creating a seaming solution that can be automated via automation robots. Both our tech partners Profactor and Haratech created samples to be sent to EMPA in St. Gallen alongside our own 3D formlock seam solution.

The following post will show you how the tryouts went as well as the final results and further steps. Enjoy!

FFF Tryout

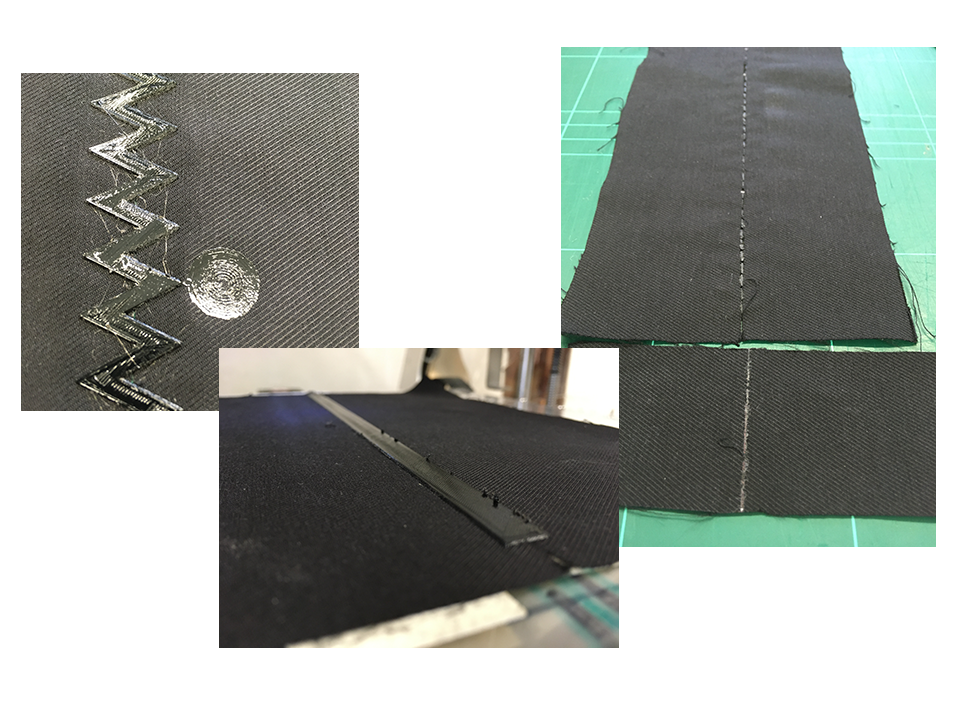

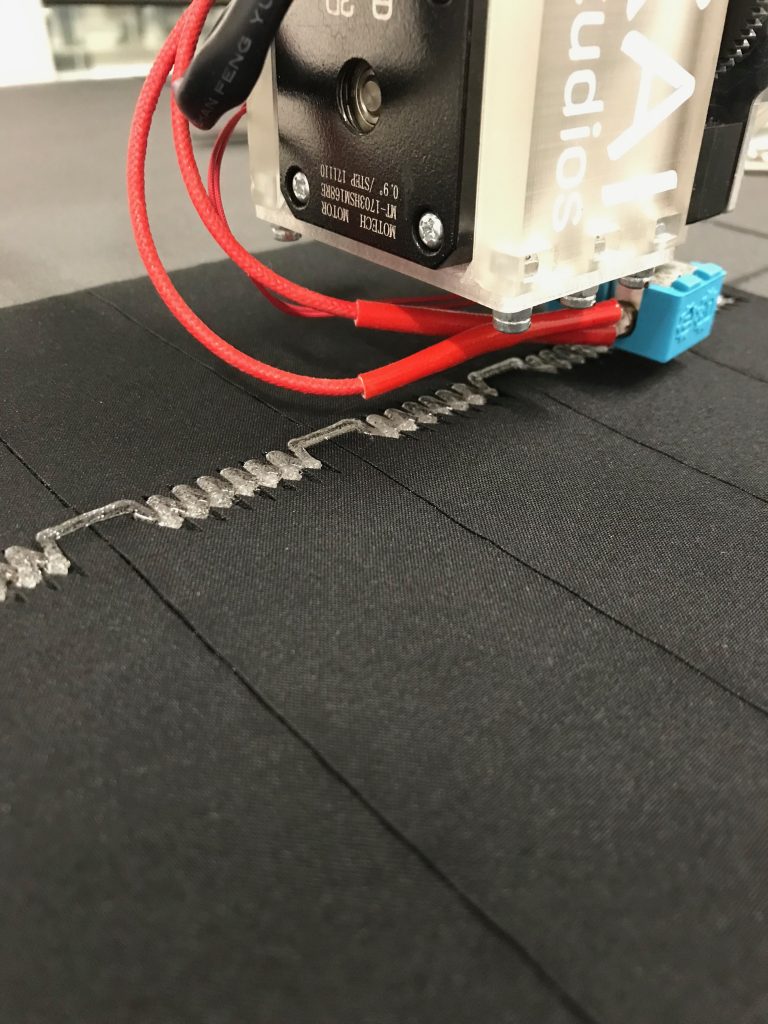

The first tryouts were carried out by Haratech, who used a FFF printhead in order to join the chosen materials together.

This particular method turned out to be a sturdy solution and the seams lasted extraordinarily well. All seams withheld a force of 1650 Newton, which is military standard for uniforms.

Dispensing Tryout

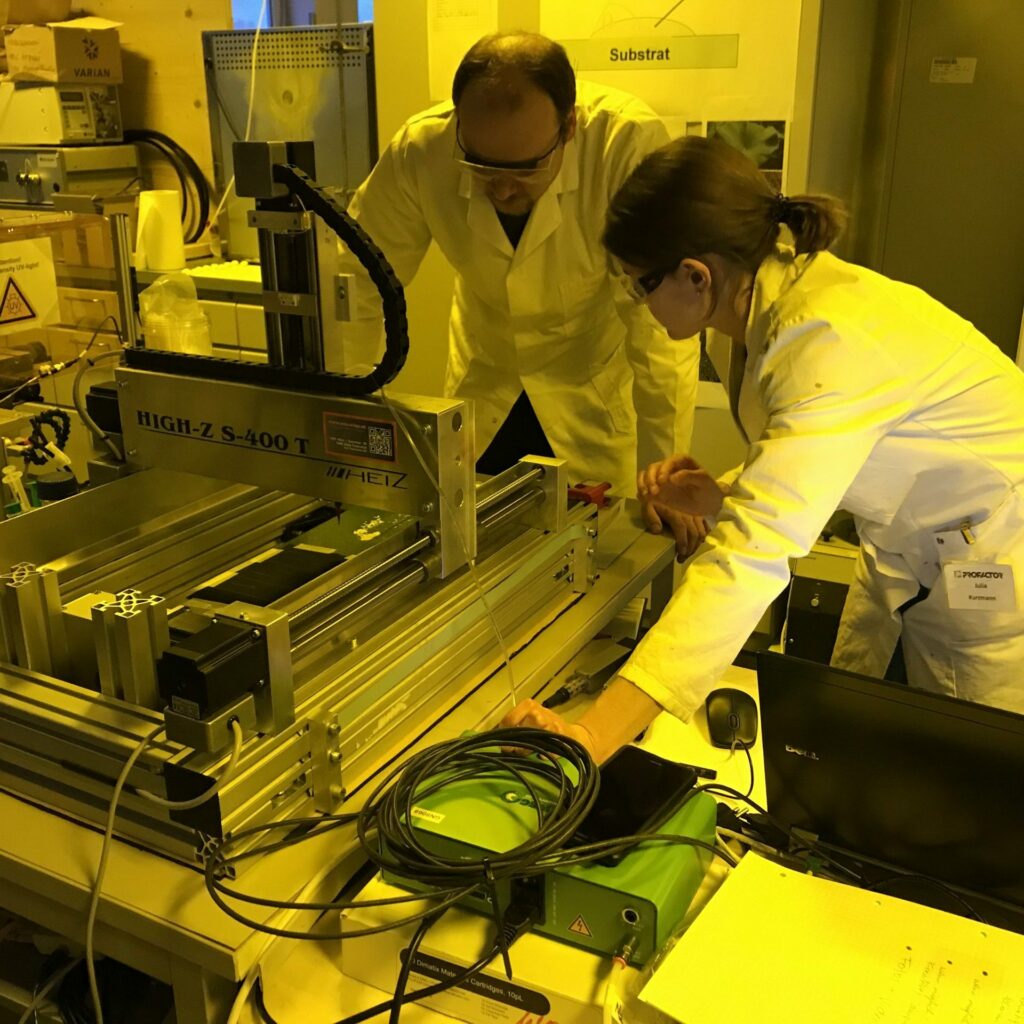

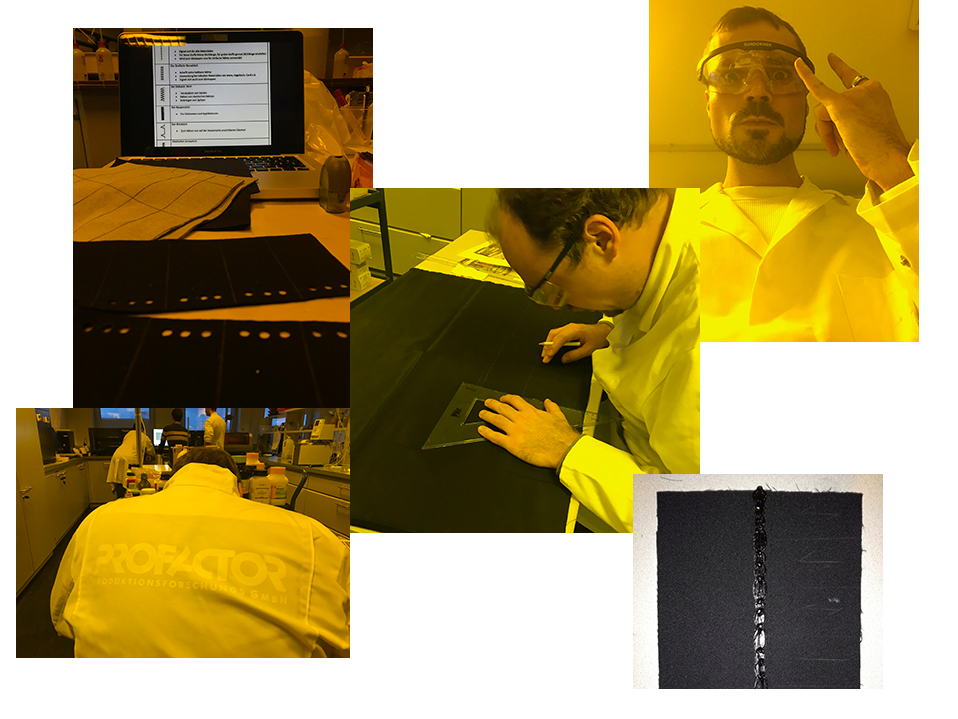

Just a few days later, we found ourselves at the lab of Profactor in Steyr, who conduct applied production research in the field of industrial assistive systems and additive micro/nano manufacturing.

Their method of using Polyurethan through a dispensing technique showed promising to us and our visit to the lab provided us with some useful insights into the world of industrial additive systems that might have an impact on our seaming solutions in the future.

While the test results still turned out satisfactory, the resistance of the seeming solution did not withstand the same standard as the FFF solution.

3D Formlock Seam Tryout

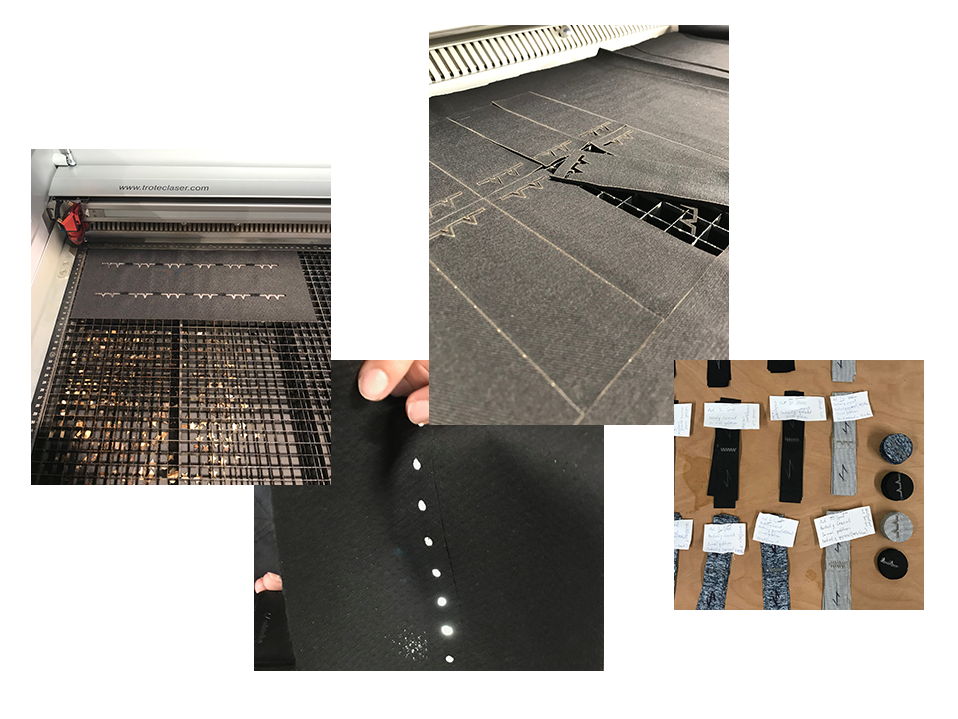

Finally, it was time to also put our own method to the test: the 3D Formlock Seam. These samples were produced using the Yokai Robot Set-Up as well as a trotec Lasercutter. During production of these samples, we also prepared pieces using transparent seams, which allowed us to add another design element to the fabric as the light travels throug the seam.

The results of the Zwick test and Tension test carried out by the Federal Swiss Laboratories for material testing showed similarly succesful results to the FFF approach by Haratech.

The Results

Taking all the results by EMPA into account, we have come to the conclusion to continue a combined approach, using the FFF technique by Haratech as well as our own 3D formlock seam solution.

Lets see what the future holds!

Yokai Team

We believe that design is a combination of functionality and innovative forward-thinking methods, that can reveal new looks of fashion products but at the same time, it should face the issues that we are challenging in the 21st century. This way of thinking gives us the opportunity to confront problems from different angles and is the result of the artistic and technical background of the Yokai team members and co-founders Michael and Viktor. The main goal of the Yokai Team is to combine new technology with well-known techniques for the creation of designs in new and exciting ways.

Image: Michael Wieser and Viktor Weichselbaumer (Yokai Team) (C) Mario Riener

Our long term goal is to build a robot based automated manufacturing system, which enables the local production of customized clothes.

Yokai-Studios Team