There is a warmth to cork, a tactile echo of its origin as a protective layer around trees. A sense of comfort which Fabio Molinas has made wearable by giving a fashionable new life to cork waste. His Re-FREAM co-creation project demonstrates the opportunities of new ecological finishings for the fashion industry, reviving the material with new purpose. The research confers renewed value to the heritage of cork manufacturing itself, a tradition whose knowledge and communities have shaped local rural economies of the Mediterranean through generations.

Surrounded by cork stoppers and their fragrant powdery dust since his childhood visits of his grandfather’s factory, Molinas has spent years approaching the woody material from every angle, from mixing and cooking to fouling and flocking.

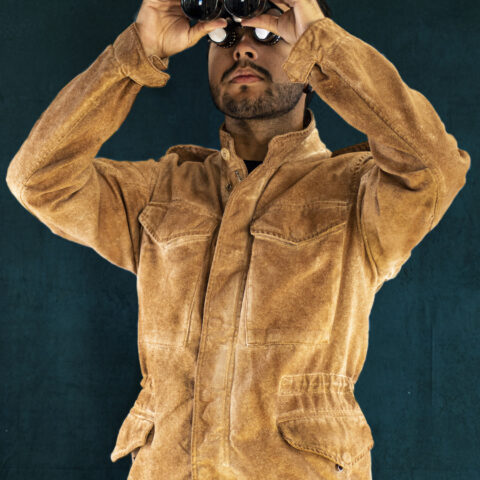

The Re-FREAM co-creation allowed him to develop a new set of industrially scalable cork waste applications. They are the bio-based Corskin, the vegetal suede-like Neobuck, and a highly innovative Nanocork textile finishing. For this finishing, garments are nebulized with a cork particle cocktail – including bio-based products and natural pigments – in a Care Applications ECOFinish system. The cork powder mist, which is adapted to each textile structure, adds a velvety finish to the fibers as well cork properties, such as thermal insulation, anti-static and tensile resistance. It can be used decoratively, as an alternative to highly toxic denim finishing methods, but also has the potential to repair and update garments.

The project combines local resources, sustainable design thinking, and a deep reflection on the material. Cork itself has much to teach us, Molinas explains : “In an economy based on speed, nature is telling us : if you want something good, you have to wait”. While uncorking a celebratory bottle takes seconds, it takes 25 years of watering and tending to an oak tree until you can harvest the prime quality cork. Highly skilled craftspeople rise before dawn to slice the bark at the perfect temperature, when it is still fresh and supple and does not stick to the trunk. Unless it is cut with surgical precision at the perfect instant, the trees die. If harvested skillfully, the tree not only regenerates new bark, but increases its levels of CO2 absorption through the process.

Then the fabrication steps begin: the bark is dried for one or two months, then boiled, then vaporized and cleansed at high temperatures, before it is cut into corkstoppers. Cutting waste is used for byproducts, such as flooring, sound absorption panels, or shoe heels. But another, finer form of waste is generated when each stopper is sanded down to the exact bottleneck size : corkdust. Burning it – which is also the traditional disposal method for used corkstoppers – produces pollution and uses energy.

Molinas decided to repurpose both the dust and used stoppers as new resources for the fashion industry. An approach which expanded with the help of his Re-FREAM partners and is exemplary in terms of sustainable design thinking : it questions traditional processes and opens them to the unexpected. Using the particles for finishings is a radically new proposal, with vast potential. Hacking the normal industrial process comes naturally to Molinas, he says, “because I’ve grown up in a generation where nothing is 100% sure, everything can change”. While traditional manufacturing becomes yet another resource to be transformed, Molinas is driven to revive it out of a deep understanding of its relevance for local communities and an appreciation of the inherent values : “It is not just about the jobs – it is about the social relationships”.

Molinas has co-founded Lèbiu SRL, based in Sardinia and Madrid, to provide eco-fabrics and vegan skin for design and fashion sectors and for introducing the new ecological applications of cork waste. The LEBIU (which means Lightness in Sardinian language) fabrics range shows a higher resistance to use – a promising outlook for sustainable garments and accessories with extended lifespans. The deposition of particles in layers allows for adaptation for performance oriented products such as footwear. Making cork wearable means its other properties – such as the high insulation it provides – could also become valuable assets for the sportswear sector. The Nanocork finishing allows for treating denim in a far more ecological manner than current sandblasting procedures. Most interesting is the capability of cork nebulization to fortify and repair garments – a procedure that opens the door to increasing garment longevity and renewal.

Thanks to additional grants from the EU, he has been able to purchase a Care Application ECOFinish nebulization machine for further lab work. Currently, he is focused on a “Made in Italy” product, as the raw materials and bio-substrates are all made in Italy, as is the leather production in Tuscany. He has recently joined up with an Italian fashion brand to begin production. Italy ranks third in the world’s producers of cork, while Portugal and Spain are the market leaders. Molinas envisions localized ecosystems like his for “Made in Portugal”, “Made in Spain” and also “Made in France” corkwaste designs.

Like all forests, oak trees are at risk of fires, desertification and climate change. As bark is the cover which protects trees from the Mediterranean winters, the trees need the cold season. While new areas could become plantable in the future as temperatures shift, another option is even more diligent re-use, for example collecting used stoppers from restaurants.

Molinas has obtained funding from the EU’s Worth and ELIIT projects has led him to work on 3D-printable cork plastic, to also create hardware for fashion, such as zippers or buttons. Another step towards a complete the range of cork waste repurposing – and towards completely enveloping wearers in tree skin.

The Project

Fabio Molinas was working on different production developments to create a range of materials (Vegan leather, Nubuck and Bio-denim) using the cork waste from the stoppers’ industry.

During the co-creation with Aitex and Care Applications in the Re-FREAM project, a waste product is valued giving a new life to something that in its natural state, is almost useless, achieving a typical worn effect of denim, a leather-like fabric, and a soft/velvet vegetal Nubuck.

Recycling is a must in the project, Thanks to the eco-finish technology by Care Applications, it is possible to achieve new effects on the surface of ready-made garments by applying chemical products or dyestuffs directly inside the washing machine.

The system micronizes the water droplets and the cork particles until it achieves a misty effect, thereby allowing its controlled diffusion on the material. As results, a part a new aesthetic collection called LEBIU, were achieved important savings in water, electricity and chemical products.

The Partners

Molinas is based between Sardinia and Madrid, and worked within the Sustainable Finishing Hub of Re-FREAM partners Aitex and Care Applications.

The Technologies

The new Corskin and Neobock materials aim to offer vegetarian leather alternatives that decrease the carbon footprint of fashion/design industries while transforming waste into a resource.

The Nanocork finish also upcycles corkpowder, while render the garments mores resistant to wear, increasing their lifespan. It also offers the possibility of repair, as well as ecological Bio-denim treatments. Nanonebulization diffuses a mixture of bio-based products, natural pigments and cork powder into textiles such as organic cotton, hemp, linen, or wool.

The cork-solution dosage is adapted to each fiber structure, ensuring a zero-waste process. The finishing can be applied directly on garments and on-demand – including for upcycling deadstock or vintage garments. Significant savings in water and chemicals are achieved, since the fabric, wrapped in a cork mist, needs only a minimal amount of water for the particles to penetrate into the fibers.

Carmina Ferri, Care Applications about the project.

Fabio Molinas’ project is a clear example of success. After his participation in the Re-FREAM project, with hard work he has managed to set up his own company from the products developed in this co-creation journey. From Fabio’s idea of the reuse of cork waste, coming from the bottle stopper industry, several lines of work have appeared:

Corkskin that he has developed together with AITEX, Neobuck which is a similar suede and Nanocork.

Nanocork started as a very experimental phase with several difficulties to face, starting with the challenge of verifying that a solid material such as cork was susceptible to being sprayed and applied to ready-made garments. An exhaustive sampling work was carried out in which very good results were obtained and which determined that the ECOFinish nebulising system was capable of spraying the cork particles.

From here, work began on the optimal recipe. This process resulted in the implementation and the upgrade of the ECOFinish system to be able to process the cork solution and obtain a recipe that, in addition to giving the garment an aesthetic appearance, increased its thermal and electrical insulation properties.

Thanks to this project, the ECOFinish system has improved its performance and a new, unique and innovative garment finishing has been achieved.

The Artist

I am a multi-awarded Industrial Designer from Sardinia. My career has been developed between Italy, Spain and Portugal. Now a days I work in Madrid in Innovation projects related to product, Interior and strategy design. My passion is to find new ways of using materials, concepts and products giving a twist of their normal uses, finding always a solution in line with the current industrial background.

“When I was a child I had to help my grandfather cleaning the workshop of the small caps factory we have in Sardinia, and besides being bored with the task I had to accomplish, I always thought what could I make with these large amount of powder that the factory produced. Only several years ago, when I became a designer and participated in Amorim’s design contest, I decided to use this waste for something better, the help the human being to be more conscious about the eco-system”

I consider myself a transdisciplinary designer, my most significant works range from the use of energy from household appliances to providing digital tools of innovation for the footwear industry in Europe.

Follow Fabio

Blog Posts

AFTER 2 ROUNDS OF 9 CO-CREATION MONTHS

MIXING ART & TECH The combination of technicians and artists gave a unique point of view for the projects developed during this nine-month co-creation period. From Care Applications we accompanied four artists from the Hub: “From linear to sustainable circular …

KEY POINTS of LEBIU – Hub Valencia

In this article, I explain what are the main values of my project. During the co-creation process, I was able to cover various socio-environmental areas that had been left apart in the presentation of the concept at the beginning of …