Marinero – 7

*Co-creation evaluation

*Knitting Mix 2 category

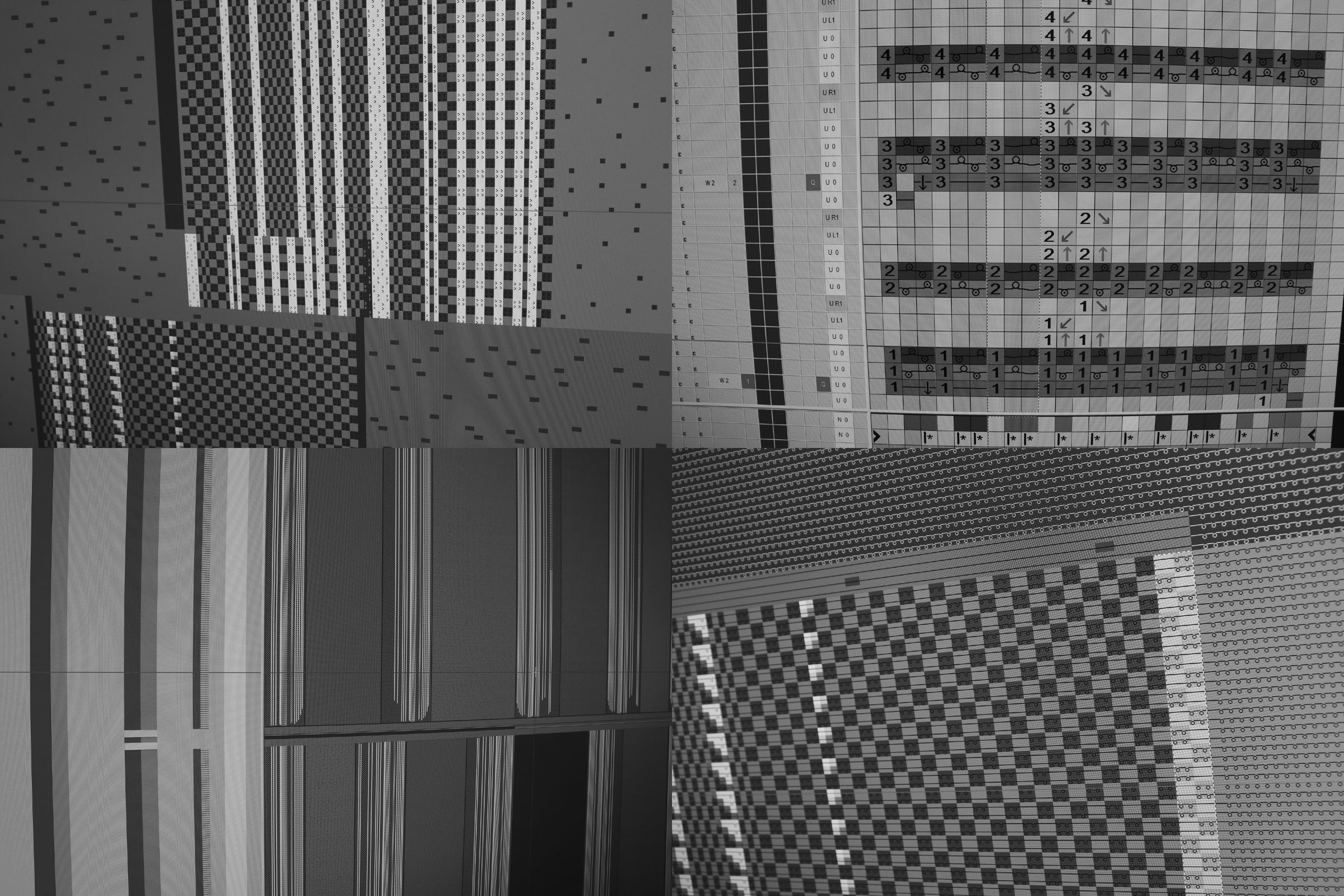

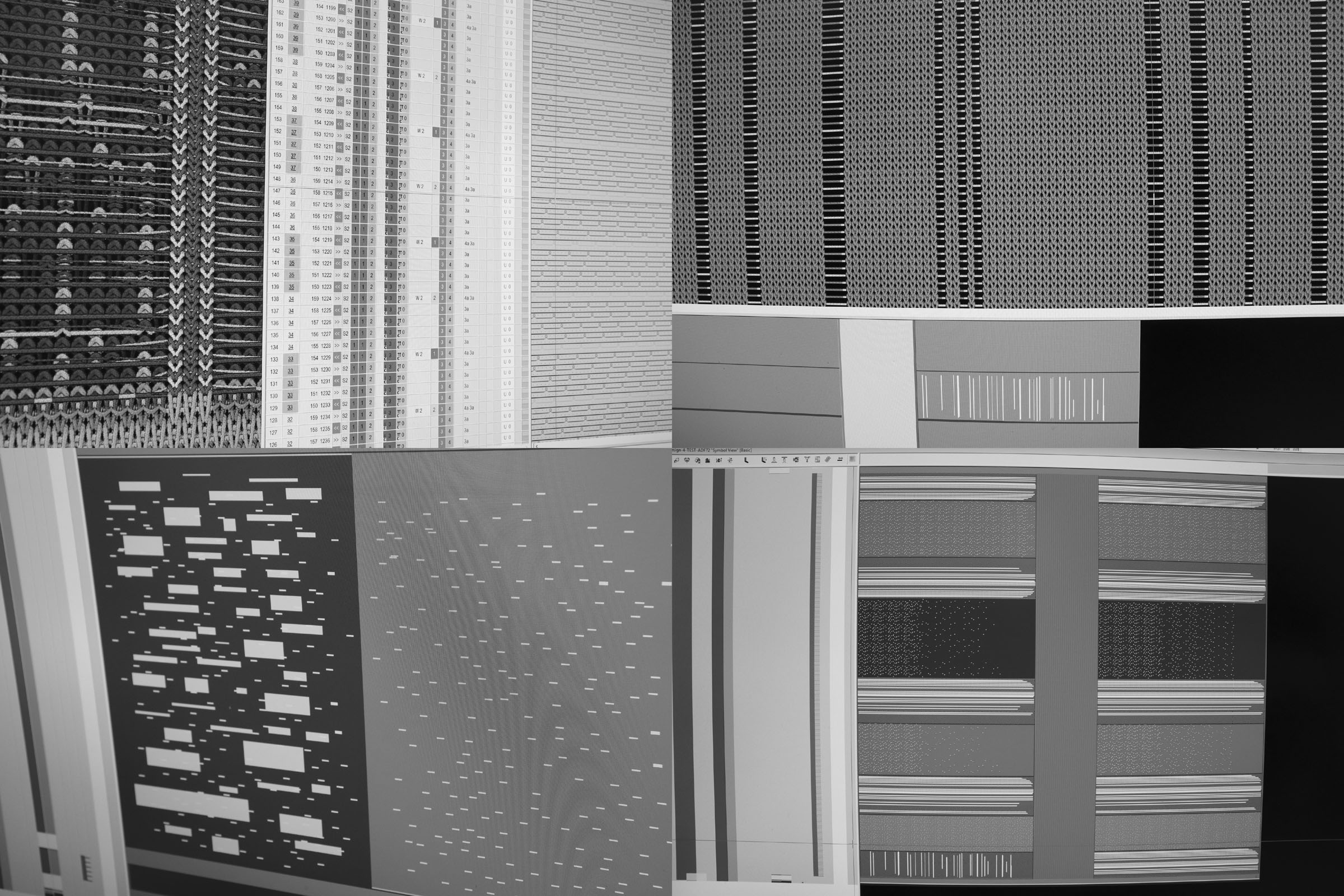

During blog # 6 I explained about the weaving production at TextileLab. During that time we were also able to start with knitting test samlpes. After the weaving production was finished, I continued working with product developer Damien Semerdjian at TextileLab Tilburg. He produced several new samples using the ADF knitting machine. I asked him to duplicate a few samples and to compare the deformation process. During the first experiment we applied water to make the fabric wet. It was very surprising to see how well the Aitex Archi-Filament was behaving within this knitting structure. Based on these results Damien and I were able to choose the most interesting samples. The next step would be to produce entire garments, based on the best samples that we selected together.

We choose to work horizontal and vertical with the ADF knitting machine, meaning that we could flip the blueprint around and use the Archi-Filaments in different directions. This was very interesting for me to see, because you can not flip the pattern around working with the weaving techniques. The tricky part with the knitting production is that if there is a flaw, meaning that a hole can be created or when a yarn is broken, the entire structure will slightly break the design. Compared to weaving, knitting is a much more delicate and fragile process. Sometimes we needed to re-start the whole production process, re-creating an entire garment. This can be a very time consuming process.

In the end we were able to create 6 garments, using several techniques for each garment. This was a great start for me to learn more about the knitting world. My idea is that I will continue this road with creating more knitted prototypes in the future. There is a lot more to learn for me in terms of new developed yarns, versus how to incorporate this within knitting structures? The first 6 garments show an experimental diverse overview on several techniques. However, in the future I would like to choose the best initial knitted result and build from there. This was the exact same way of working that I experienced during the first 6 years, experimenting with several jacquard weaving techniques. I feel that with project Marinero we reached a high level with weaving and created an experimental initial start with knitting. I would like to bring my knowledge with weaving and knitting to a more balanced level. Maybe we can bring those 2 worlds together in the future, complimenting each other throughout a new collection.

–

*Weaving effect test

During the weaving production Judith Peskens and I were working on the Mix 1 category. At first we wanted to play around with several yarns, to combine the Re-FREAM yarns with yarns that TextileLab had available. In the end we decided that this was too much and I did not see that this way of working would fit with the other categories. So, we decided to just not make it complicated and use the Re-FREAM yarns for the Mix 1 category. However, the garment sample was already created and I had the idea to use it for the first rain experiment. The garment was stitched in my studio in Arnhem and I brought the dress to the roof top. I used 1 black painted mannequin as a base for the fabric. The time lapse camera was placed on a single aluminium tube, right in front of the mannequin. It was also a good moment for me to find out how this camera works. The process was recorded for about a week. It was good for me to see how the Aitex Archi-Filaments reacted with the rain. The early July weather in Arnhem has been crazy until now. We had rain, sun, extreme humidity, strong winds and hail all together in 1 day. I am looking forward to the other remaining 30 weaving garment prototypes.

–

*Knitting effect test

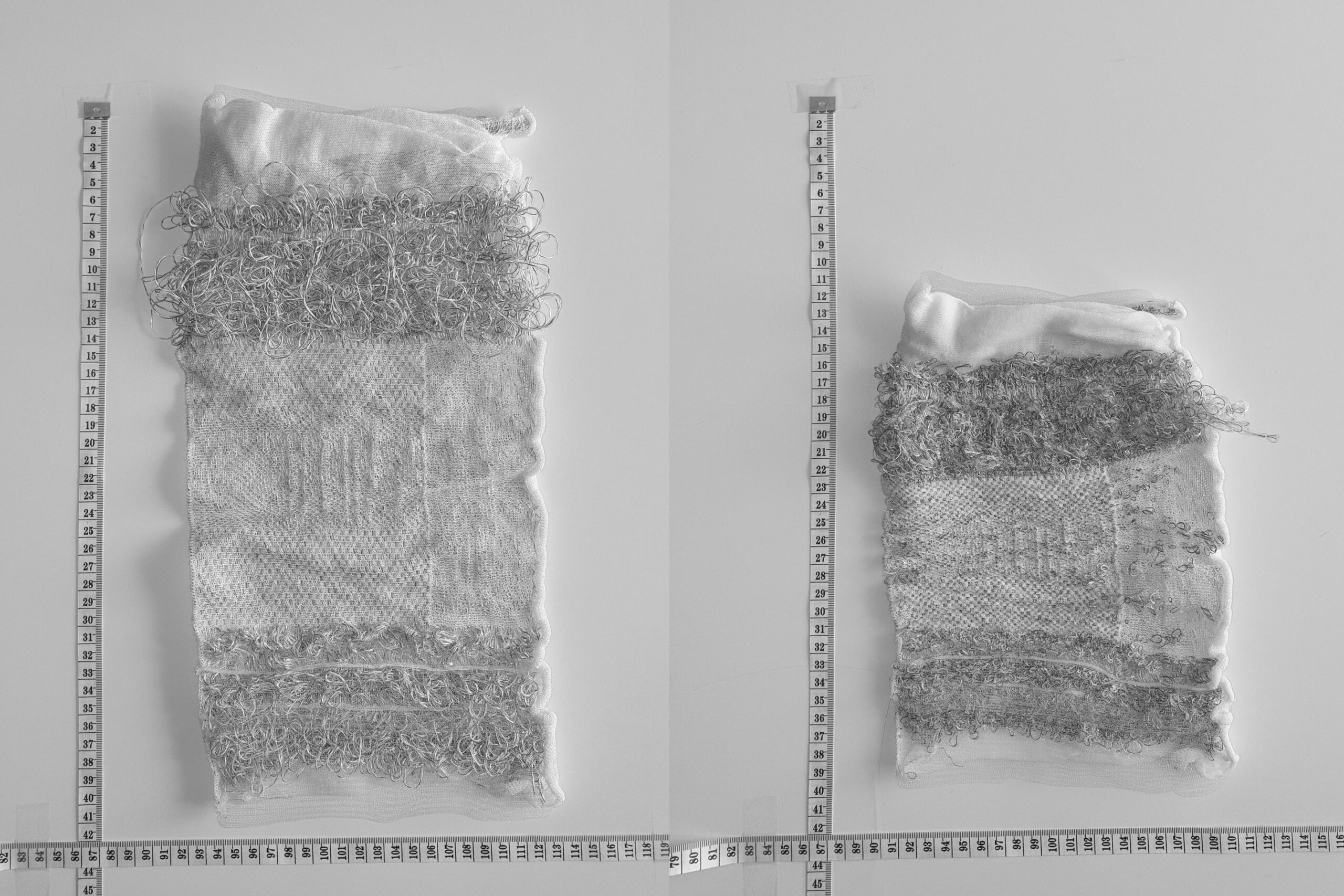

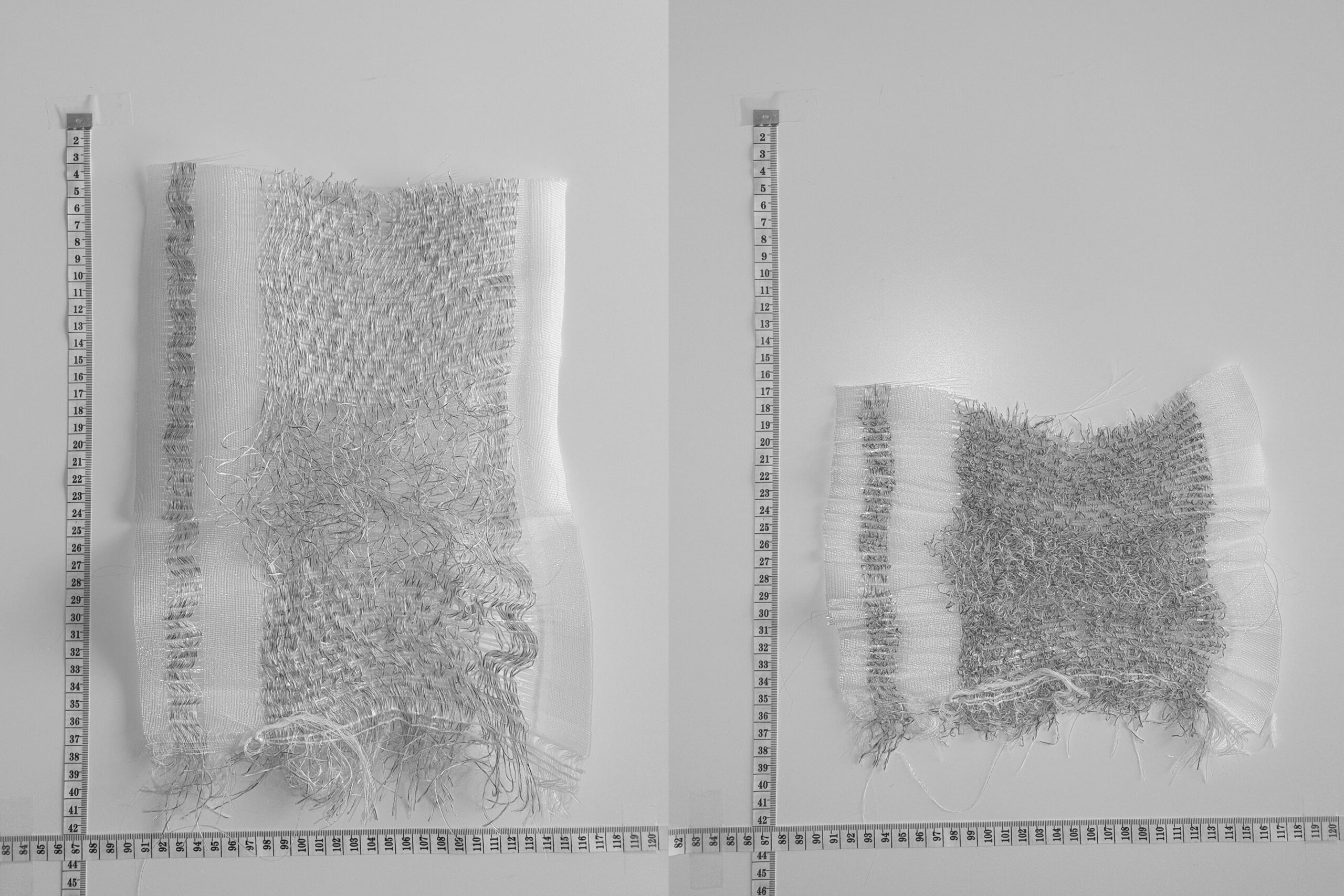

During the knitting production several extra garments were produced, these garments were not optimal enough. For each design Damien Semerdjian needed to produce the entire garment twice or even a third time in a row. I used all these flawed test garments, in order to make more roof top rain experiments. This was great for me to see the fabric effect, but also interesting for Damien, because we saw that some techniques were not working out well. We were able to adjust some details, making the final knitted designs more optimal. The interesting thing about this is that we can work more organically throughout the whole process, producing test garments and instantly seeing the deformation effect. The initial tests showed that the Archi-Filaments already change size and shape up to 50%. We divided vertical lines throughout the design of the garment, showcasing detailed technique diversity. Throughout the fabric frame we locked all the Archi-Filaments, this helps to keep the shape in it’s place. Throughout the centre of the fabric we made several parts more fragile, allowing the fabric to burst open and created several detailed smocking effects.

–

*Studio developments

The final step of creating the Marinero garments was to stitch all the designs in my studio office. The process is quite simple, the patterns are rectangular and easy to fold together. The fabrics are fastened with pins and stitched with the industrial sewing machine. I did not see the official designs until I unpacked them all at my studio in Arnhem. It’s always nice to unpack the designs and see the final outcomes of the fabrics. Each design has a number and relates to the other one following up. It’s a very thoughtful and organic process. Everything is linked to each other and it all makes sense once you see the collection overview.

I started working with the seaweed and knitting category. The difference between the two is that the woven designs need to be cut from the roll. With the knitted designs I did not need to cut anything. Each design was already finished and ready to stitch with the machine. The majority of the fabrics are woven textiles. So I will need to cut all remaining categories from the fabric roll. During the cut it is important that this needs to be done in a sharp and clean way, because this cut already creates the finishing of the woven garment. During fabric production we applied a special finishing yarn within the first few cm’s of each textile. This finishing keeps the entire design in its shape.

–

*Empa lab results

The end of the first call of Re-FREAM is near and my collaboration with Empa has come to it’s final stage. It was very interesting and refreshing for me to learn about this amazing company. We were able to send woven and knitted samples to St.Gallen. Several test were done by collaborative scientist Agnes Psikuta. The interesting part is that we tried out several treatments applied to the fabrics, to see how the fabrics for example behave when washed inside the washing machine. An overview of test results was presented to me, showcasing the dimensions and fabrics changing deformation. Next to that I also received an Application Potential Analyses. This will help me to think about commercial adaptations of the developed Re-FREAM yarns and filaments.

My personal thoughts are that I would like to follow up using the melt coating technique. These samples were produced with Wood KPlus in Linz. With Aitex in Alcoy I was able to work with the dip coating technique. The results are artistically very interesting, but for a commercial adaptation it would be too difficult and fragile to reproduce. I would say that with project Re-FREAM we reached an interesting new level of innovation, a hybrid balance between artistic and commercial outcomes.

Observation test Agnes Psikuta @ Empa

Knitting fabric samples:

- SPRAY > before = 40 cm & after = 38 cm

- STEAM IRON > before = 40 cm & after = 28 cm

- WASH > before = 40 cm & after = 26 cm

Weaving fabric samples:

- SPRAY > before = 36 cm & after = 18 cm

- STEAM IRON .> before = 36 cm & after = 19 cm

- WASH > before = 66 cm & after = 39 cm

Conclusion lab experiments = knitting samples need a combination of moisture and warmth, in order to deform the fabric. The weaving samples show the full deformation process, just by using cold moisture. These samples were adapted into 3D cloth software, by using the smocking effect tools > going from 2D to 3D around the body. The simulation pattern is structured by adding dark horizontal lines, showcasing where the Aitex Archi-Filaments are included inside the fabric pattern.

Final recommendations: improve future samples of Archi-Filament > current prototype = going from 2D to 3D ( but not back again towards 2D ). It would be interesting to research improvements on the reversible effect of the filament. If successful, a wider spectrum of applications would be possible.

–

*Installation update

The final update for the installation plans have been completely changed during the corona crisis. I have been in contact with project partners Aitex, Empa and Ars Electronica. Initially we agreed on shipping the installations to Spain, Switzerland and Austria mid July. But I changed my mind to keep everything inside the boarders of the Netherlands. This way there is no big risk for me to travel and put myself in rapid shifting lockdown situations.

Image: Rooftop B46 Kema chemistry laboratories Arnhem

After a long search for several locations, I came to the conclusion to just pick the strongest option. We began to think big, but in the end it’s best to zoom into the essence of what you are doing. In my case I just need a good roof top, that is big enough for my installations. My journey all over Europe brought me back to the place where it all began, my studio office rooftop. After I cancelled all the installations in Europe, I went back to my own rooftop in Arnhem and I came to the conclusion that all installations would fit on this exact spot. Next to that, I could record the time-lapse of all installations combined at one location. Image-wise I believe this would be the most powerful documentation frame. I am happy about this outcome.

The following updates will only be about the installation process and final outcomes of the project.

–

For more info visit: www.studioadaptiveskins.com