Fragments Garments #9 – Material Sourcing & Sampling Tests

Sustainable Fabric Sourcing

For each of my projects, I usually source fabrics locally. As my main partners were in Alcoi, I decided to scout fabric suppliers in Spain. I had the chance to get help from Blanca Gomara from B2Fabric which is a specialist in sustainable fabrics based in Madrid.

The first fabrics which caught my attention were two recycled blended wool with synthetics and a food-waste based leather-like material called Pinatex. Both were working well with laser-cut and micro-nebulization processes but unfortunately, the recycled wool existed only in dark colors so we could not dye them on-demand as we wished. As those two materials were produced in the UK and in Italy, I decided to expand my fabric sourcing to European suppliers.

Parisian Hunt for End-of-Collection Rolls

As it was difficult to find adapted fabrics combining properties needed for being used with the laser-cut machine and the micro-nebulization processes in Spain, I went back to my usual French fabric suppliers. In Paris, we enjoy a vivid resale market for end-of-collection rolls of luxury houses fabrics, which allow us to buy high-quality products destined to be wasted for an interesting price.

I ended selecting eight different materials:

- 1 indigo-dyed blended denim with synthetic

- 2 uncolored types of wool (one thick, one thin)

- 3 different kind of Pinatex (an undyed one, a mineral shiny pearl finish, and metallic gold)

- 2 already dyed types of wool (a thin dark purple and a thick blue-green one)

Sampling Tests

With my partners from Care Applications and Aitex we defined a series of tests that should be conducted on every selected fabric:

- Evaluation of g/m2 of fabrics I bought from resellers for which we did not have the technical sheet.

- Laser-cut test on untreated fabric.

- Softening treatment

- Waterproof treatment

- Chemical dyeing

- Natural dyeing with acacia wood powder

- Softening treatment + natural dyeing

- Waterproof treatment + natural dyeing

- Laser-cut test after textile treatment

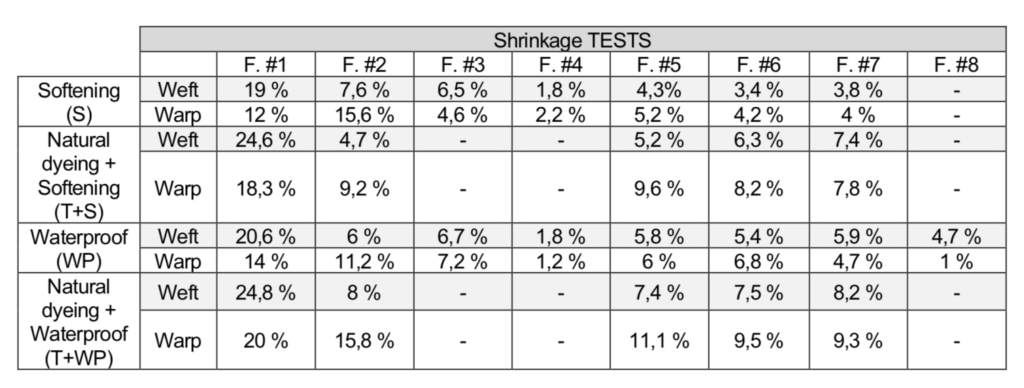

- Shrinkage percentage calculation post-textile treatment

Of course, the already dyed fabrics (purple, green-blue wools, and the denim) were not tested with chemical and natural dyes.

As we envisaged to use the micro-nebulization process to offer on-demand dyeing for minimal textile, chemicals, and water waste, we needed to know how the dyes and post-treatments were impacting the fabric in term of shrinkage. As the latter can be different on the weft and the warp, both have been calculated.

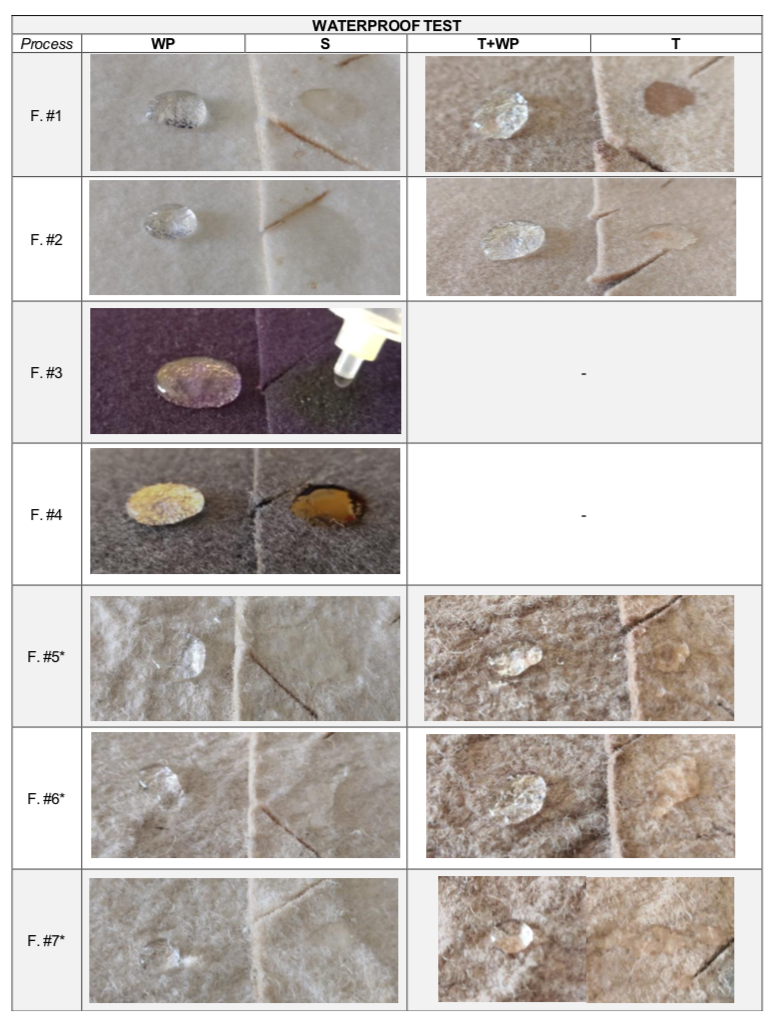

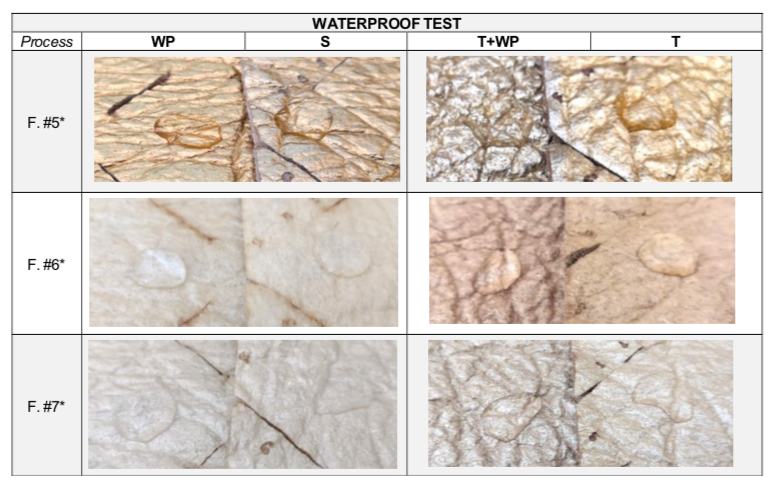

The waterproof treatment worked well on all fabrics, but tests revealed that it was unnecessary to treat the Pinatex materials as the external surface was already water-repellent.

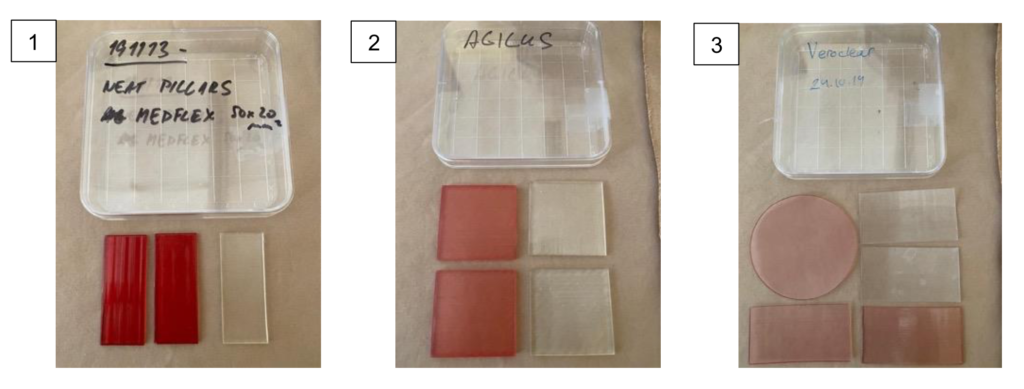

Dyeing 3D Printed Parts

As explained in the previous post dedicated to 3D printed clothing fasteners, one of our research questions was: “is it possible to dye on-demand not only a customized garment but also the corresponding clothing fasteners”. In order to find answers to such query, we proceeded to dye a sampling test on different transparent 3D printing resin.

As you can notice above, all three 3D printed materials have been dyed with the same quantity and type of color pigments, and the MedFlex resin is the one that works best with such process.