When sustainability meets 3D printing technology – ‘Re-Textile 3D’ by Ganit Goldstein

In the following months, COVID 19 has been challenging our co-creation process. We continue to work with my partners: Haratech, Stratasys, Profactor, and F&T – in a complete workflow remotely, catching up with progress along the weeks. Working remotely offered a different kind of challenge – to develop virtually 3D design tools and processes in a completely digital cycle. I was working on the development of 3D printing techniques within the workflow with Stratasys preparing the final prototype, as long with new developments using a Home 3D printer. The study of multi-material was the main research topic, making new materials combinations that challenging the current 3D textile production.

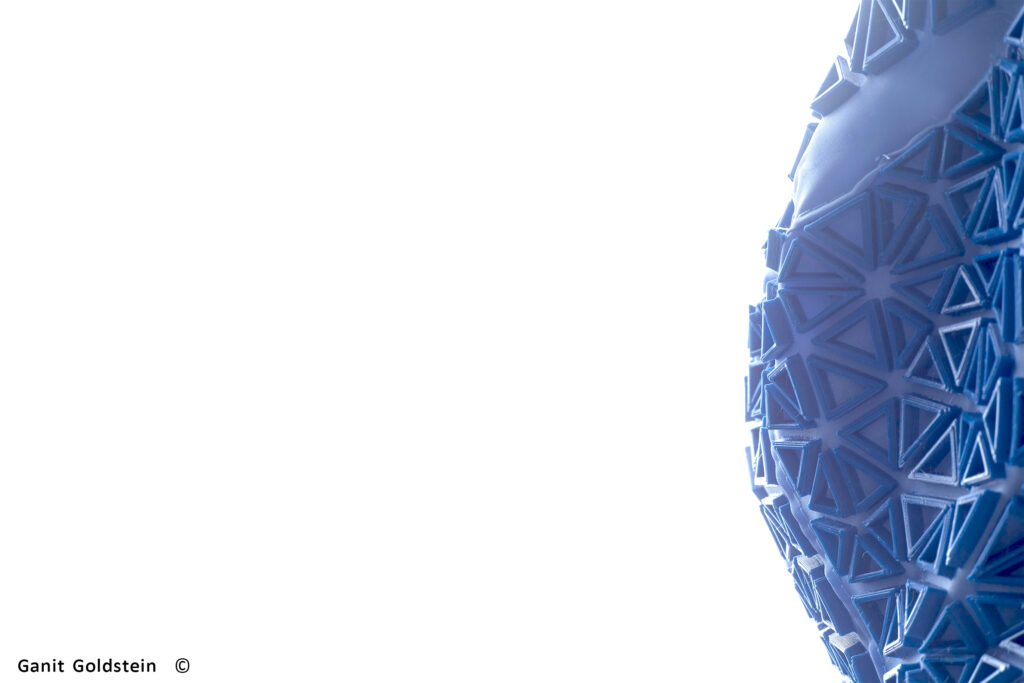

One of my missions from the start was to build a new kind of system that presents a sustainable workflow – from starting to design on 3D scan to the whole production of 3D printing from recycled water bottle waste. I was researching the new possibilities of recycling filament production, as long with sustainable fabric manufacturing around Europe. As times passed by, the new approach has become a reality, introducing a completely 3D printed garment, from ocean plastic waste woven with the use of 100% recycled filament for the developments of 3D printing parametric design.

“The possibility to use materials within the 3D printing process –

when materials can be transformed through digital elements fascinating me, Within the study of new material cycle and re-use matter – that otherwise considered as waste.”

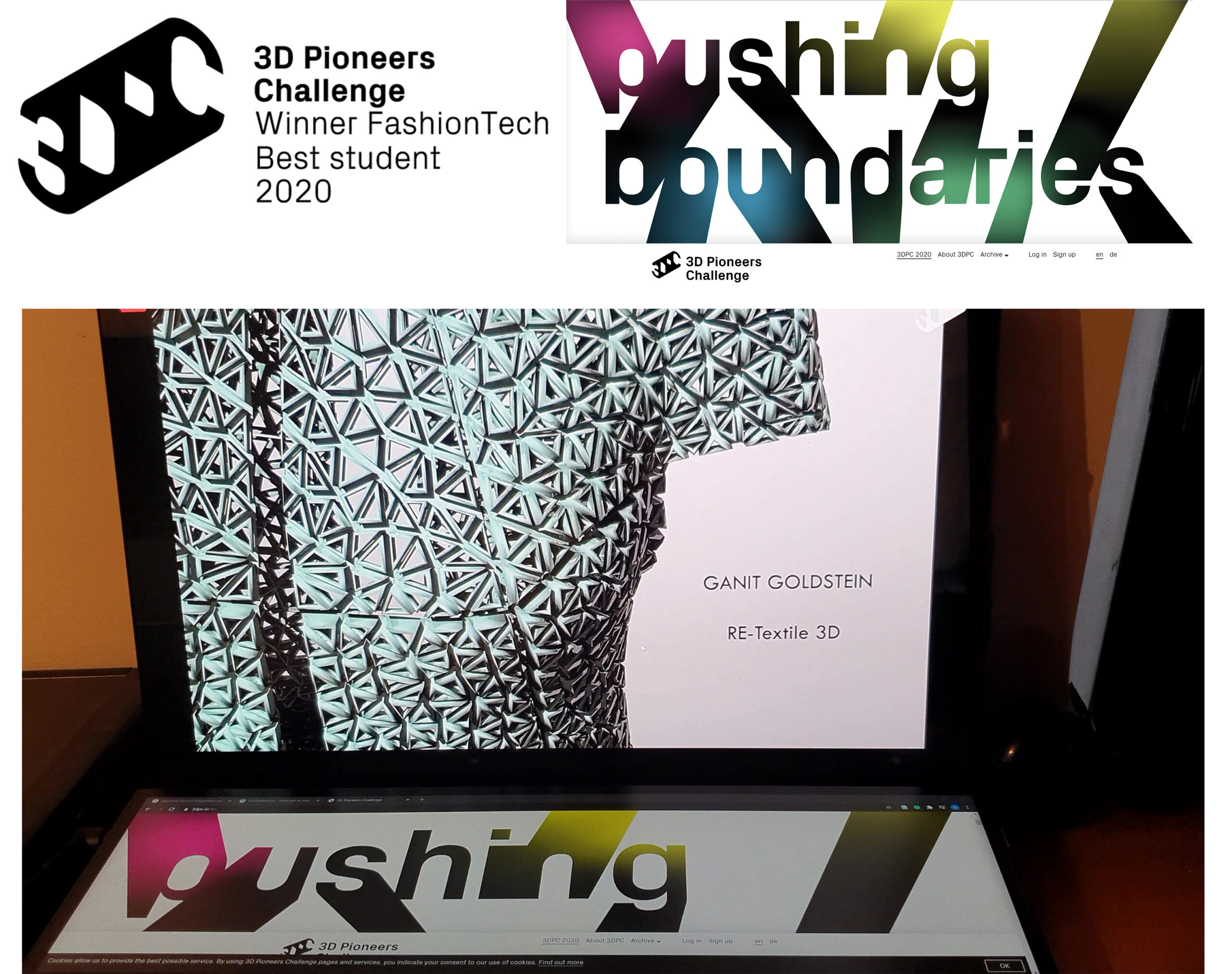

The new project titled as ‘Re-textile 3D’, won the first prize in both categories ‘Fash-Tech’ and ‘Best Student’ Project for the ‘3D pioneer challenge’, the biggest competition for pushing the boundaries of AM developments within design and research. Supported by Messe Erfurt and Rapid.tech3D , the competition this year was shifted to a virtual event presented in the award ceremony on July 15th.

‘3D pioneer challenge’ virtual ceremony presenting the awarded Fash-Tech & Best Student project - 'Re-textile 3D' on July 15th

The process consists of 3D CAD manipulations from 3D to 2D flattening, using parametric software for building a unique pattern based on the body scan. Finally, the 3D pattern generates to 3D printed model aiming for the outcome of a unique, 100% sustainable garment production. The process combines in harmony the cycle of reused materials to produce unique outfits – making new from re-used existing materials.

The project has been in exhibition at the “Leonardo da Vinci”, Museum of Science and technology in Milan as part of the Ro-plastic Prize finalists exhibition curated by Rossana Orlandi and displayed during Milan Design City September-October 2020. The exhibition consists of five categories to produce projects using innovative recycling plastics including the ‘innovative textile’ section, which aims for new, inspiring project workflow by using recycled plastics in the world of textile productions. The project will be in view until October 10th 2020.

Re-Textile 3D printed dress at "Leonardo da Vinci", Museum of Science and technology in Milan - until 10th October 2020.