Trip to Hub Linz

TRIP TO STEYR @ PROFACTOR

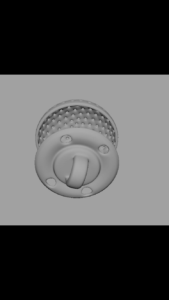

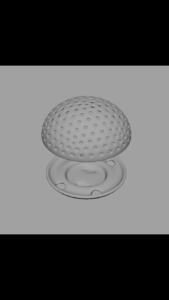

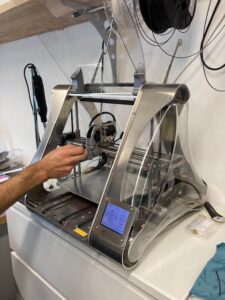

I took a trip to Hub Linz to visit Profactor to develop some buttons that could be screwed opened and closed so that a scented piece of fabric could be inserted into it. The idea was to be able to develop small accessories that can be interchanged between one’s own garments and personalise the aroma that one would want to apply and carry around. The idea that aroma can also be functional (in the case of lavender, keep moths away and prevent moth holes and thus elongating the life span of a garment) and health beneficial (aromatherapy as a reference to the well-being of a person – more research to do on this).

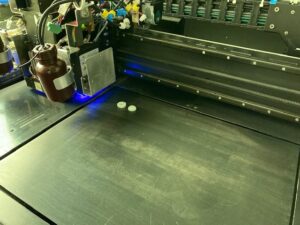

The structure was a 2-piece domed button with a perforated and hollow top. We encountered a few difficulties with this design. The perforations were too small for the 3D printer to execute and the wall was too thin for the button not to collapse in the washing stage. A new design was made with larger perforations and a thicker wall which we are in the process of testing.

The process of seeing how the machines work was eye-opening as I had never had any experience with them. I was also able to understand how important working with 3D softwares was in able to really execute a product to the best of its potential. I will be working on trying to get more skills in this field as I could definitely use more practice.

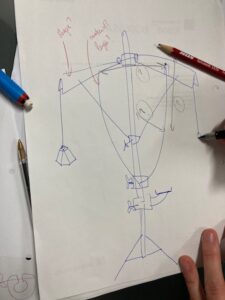

TRIP TO LINZ @ HARATECH

My trip to Haratech was also quite interesting and productive as the co-creation process really took the direction of the outcome in another direction, which I was very happy with. Working with Guillaume was great since we were able to discuss the key priorities of why I wanted to make a 3D mannequin, and instead of wasting material and time, we stripped down every element of the design which was not essential and came up with a more efficient structure that would be portable, more lightweight, and would be able to re-scent jackets once their microcapsules faded.

Guillaume’s expertise in his field and my expertise in mine created a great collaborative discussion and environment. The final prototype is in the works and still to be tested.

In regards to sustainability, I see 3D printing as a viable solution for first prototypes to later be developed or reproduced in more sustainable materials, but at least as a first sample of what an idea can turn out to be.

A great experience to say the least!