Fragments Garments #5 – Co-creation residency in Hub Linz (Part 1)

Residency Objectives

- Develop an articulated and customizable 3D printed high heels pair of shoes combining soft and hard printing materials.

- Develop 3D printed customizable and reusable clothing fasteners, to be produced on-demand, to be then dyed using the micro-nebulization process of Care Applications.

As my co-creation residency at Hub Linz had two main objectives, this trip to Austria review will be split into two parts, here is the first opus focusing on the 3D printed high heels conception.

3D Printing Technologies

Elena let me first visit their facilities, meet the scientists, discover the equipment, and subsequently explained to me the different 3D printing technologies and their specificities.

- FFF – Fused Filament Fabrication, sometimes best known as FDM –Fused Deposit Modeling which is trademarked by Stratasys, another Re-Fream partner, is a 3D printing process using a heated extruded thermoplastic filament which is deposited one layer at a time on a horizontal platform. It is the most commonly used technology because of its low machine and material price but has a low resolution and accuracy. Better to be used for basic proof-of-concept models and simple prototyping.

- SLA – Stereolithography Apparatus which uses a laser selectively illuminating the transparent bottom of a tank filled with a liquid photo-polymerizing resin. The solidified resin is progressively dragged up by a lifting platform. This process has a highly versatile material selection and high accuracy with fine details, it is used for functional prototyping, patterns, molds, tooling, and medical devices.

- Polyjet process which sprays small droplets of liquid photopolymers in layers on a horizontal platform, instantly cured by a UV light. Polyjet allows combining different materials, colors, transparency, and material hardness in one sole print. It is the most advanced technology, normally reserved for industrial applications.

High Heels Shoes Conception

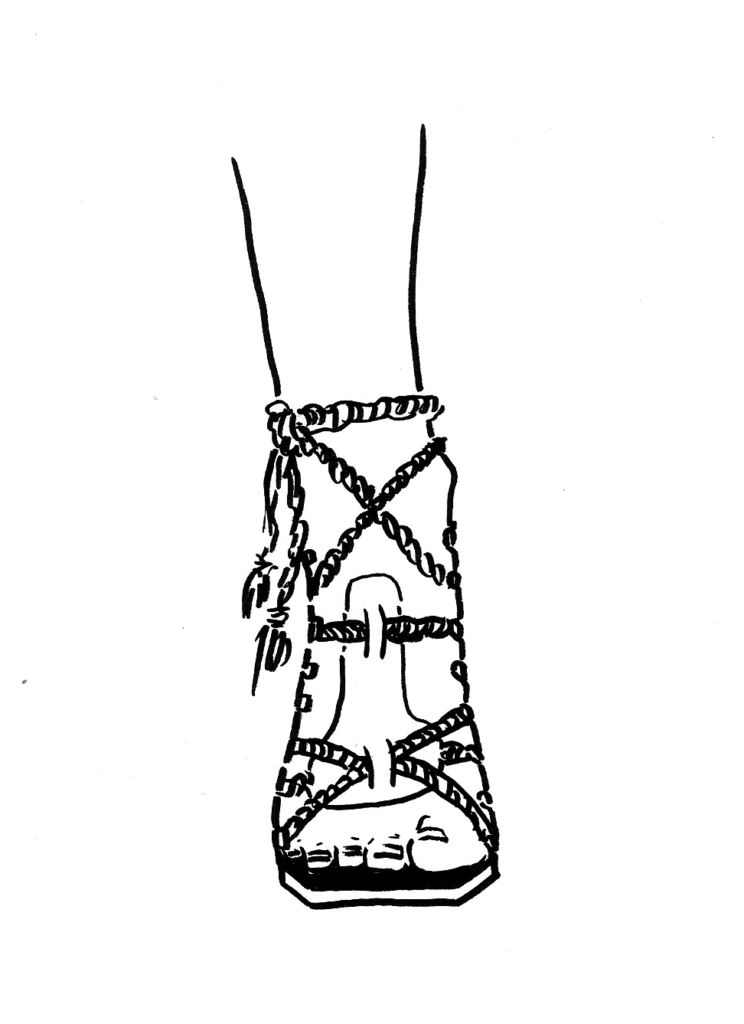

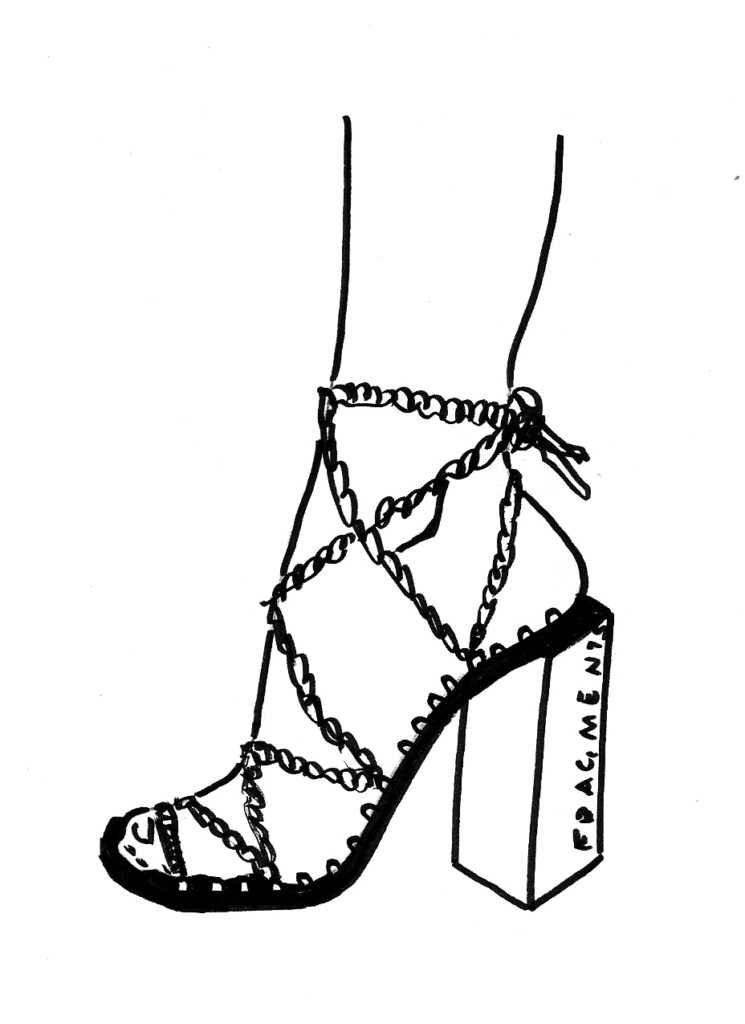

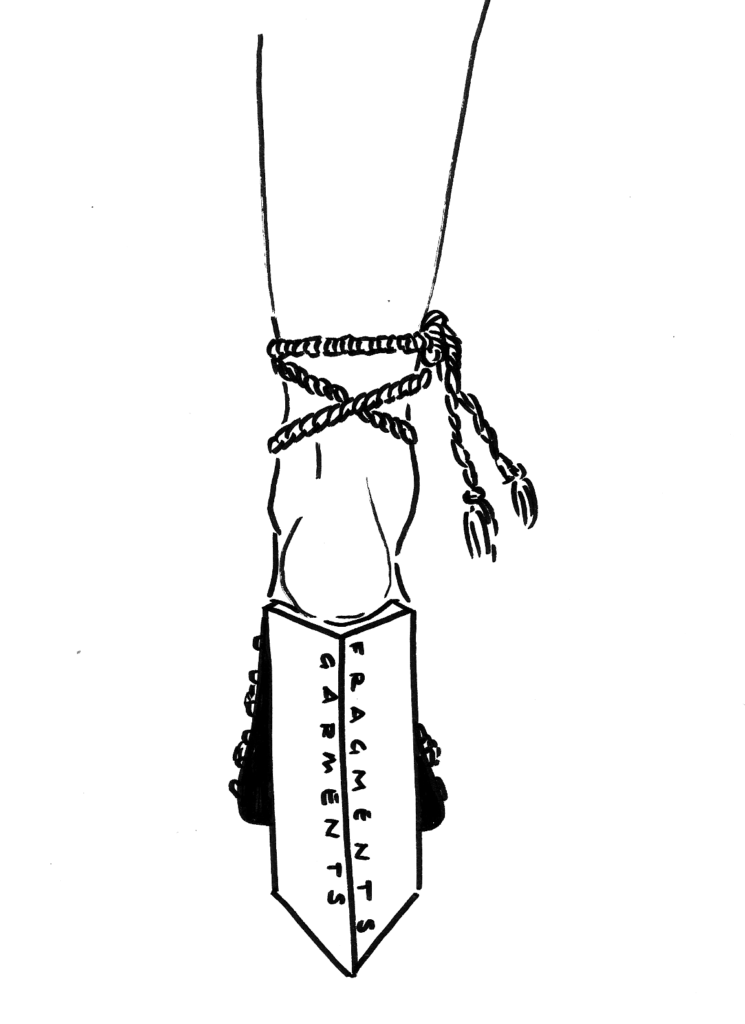

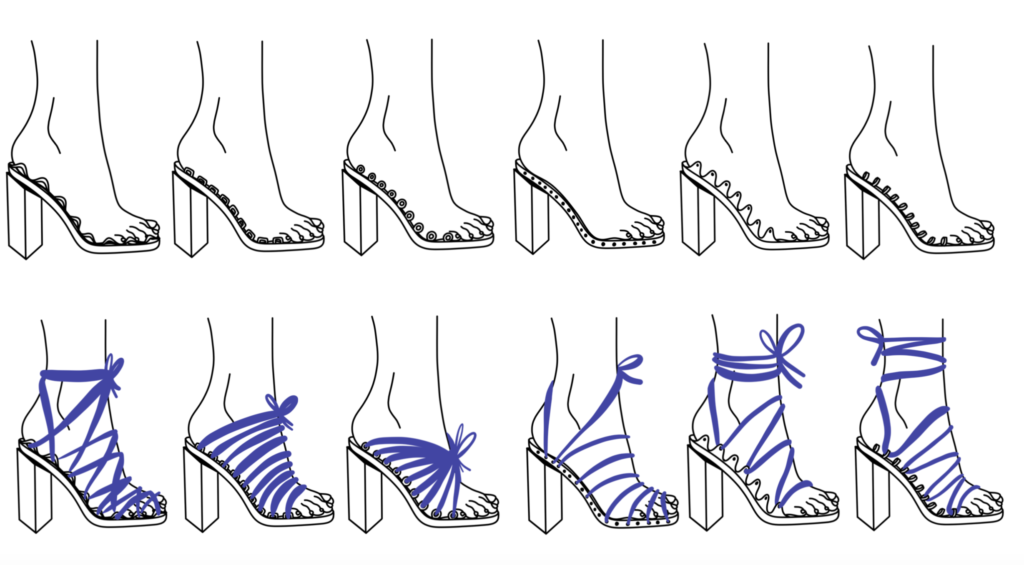

To complement the modular clothing collection, I wanted to create a versatile pair of shoes that could be worn in many different ways. I decided to focus on high heels sandals, to lighten my 50’s inspired silhouette with its mid-calf full skirt. Iconography researches led me to envisage using dismountable lace to style the shoe, this one could as well be replaced by a ribbon, a rope, or a string.

The mood board let me conclude that I wanted to create a simple sole on high heels with numerous side attachments, in order to allow for the consumer to freely style the lace. After defining the shoe concept and style, I focused on the high heel shape research.

First Heel Shape FFF 3D Printing

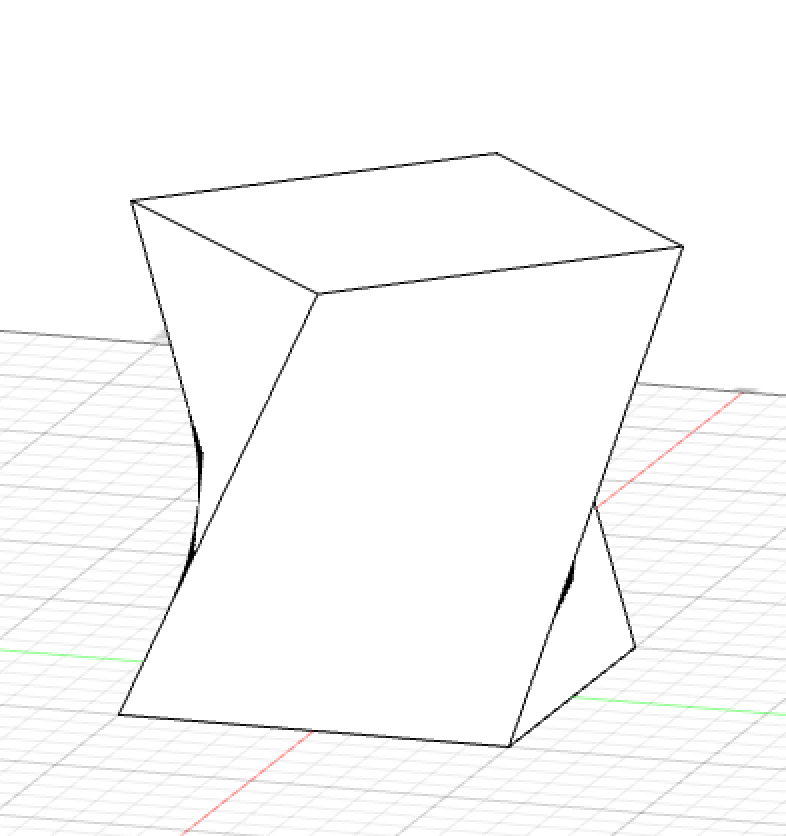

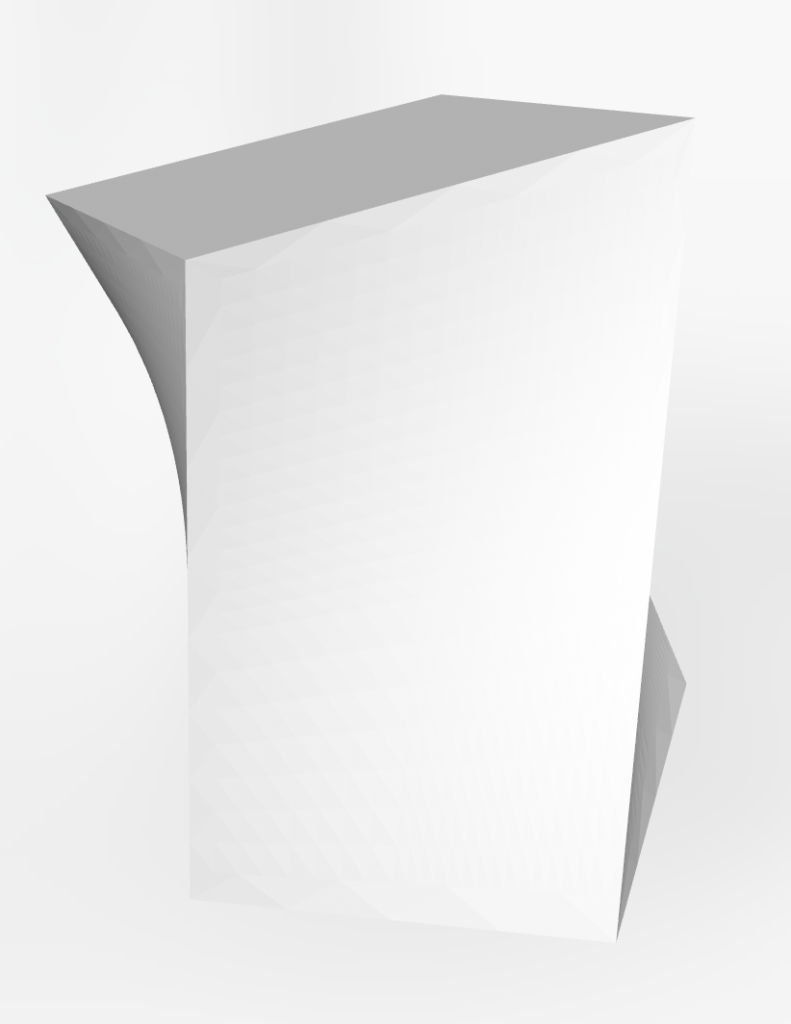

The first heel shape is inspired by a very classical rectangular block heel and by helical stairs. The idea is just to rotate the base square of 45°and to loft the external shape, so as to create an innovative heel shape based on very simple geometrical elements.

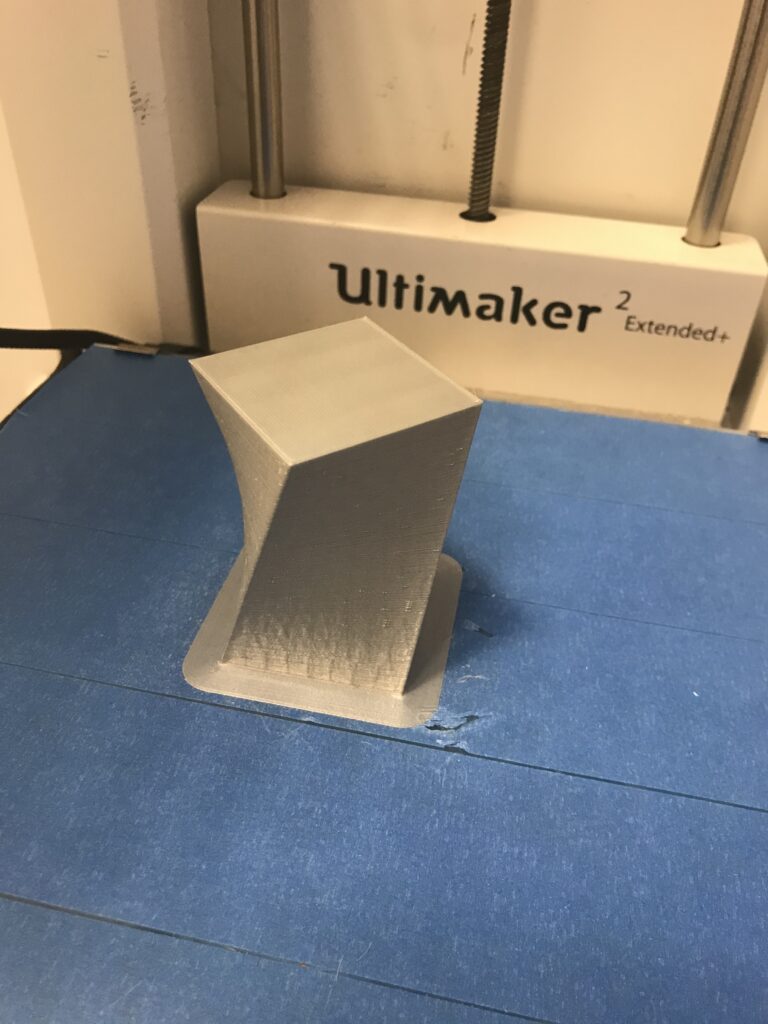

Above you can see the conception process from the inspiration image to the shape modeling on a 3D modeling software, to the material rendering and finally the heel FFF 3D printing using a sustainable PLA silver filament which is fully biodegradable.

2nd Heel Shape FFF 3D Printing

For the 2nd heel shape, I wanted to keep the interesting helical twist, but also to give the illusion of a modular conception of square blocks added up one to the other to recall the zero waste square module used in my seamless modular clothing collections.

Once again we choose a silver PLA filament because this shiny color gives the best shape overview in photography. If this prototype seems really convincing, this has not been the case every time! Below you can see three of the other attempts we did that were not that successful.

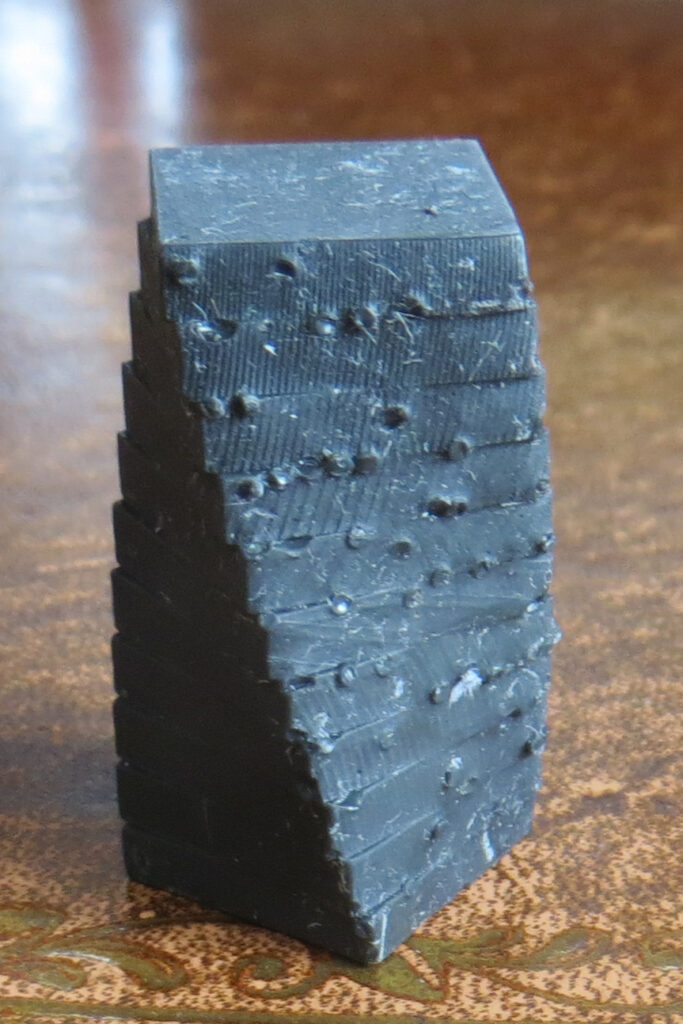

On the left, the first FFF print with too low a resolution presents a not well-defined shape. In the middle, the SLA test shows asperities caused by not well-placed shape support parts. Finally, the third Polyjet print on the right has been made in a rubber-like material called Algilus which is too soft to sustain bodyweight in a shoe heel. To conclude a successful 3D printed prototype requires a well-conceived 3D model file, a smart positioning of support parts, a high-resolution finish, and perfect adequacy between the chosen material properties and the object dedicated function.