Laser Technology

About the project

About the Technology

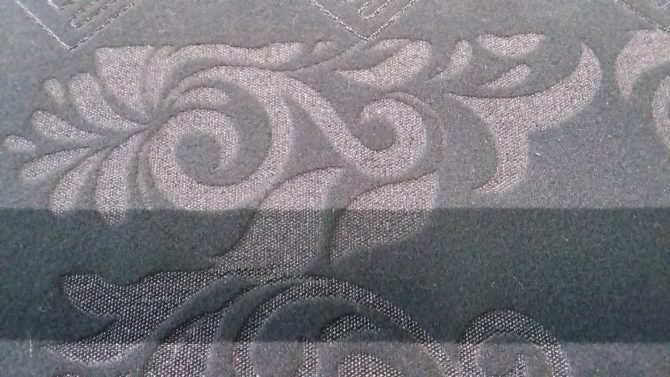

One of the most polluting phases of the production processes in the clothing industry is the finishing process, e.g. fabric decoration. Research shows that laser technology currently is the most eco friendly and sustainable application that can be used to decorate clothing and fabric. Not only did the laser technology stand out as a viable and efficient technology, but it also allowed designers to innovate products and designs.

The laser marking on fabrics and garments is based on the sublimation capacity (this means, from solid to gas) of the dyes with which these tissues are dyed, by application of a high intensity heat source.

Main characteristics:

- CO2-based laser which can be used at different stages of the production cycle.

- Use of CorelDraw X7 software.

- Laser mark area up to 1×1,2 m.

Usual Areas of Application

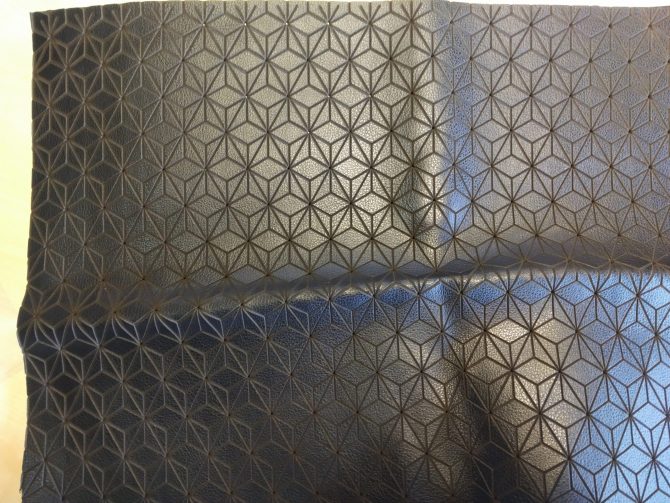

This novel technology was especially developed for sustainable textile finishes in order to introduce design and cut effect on different types of textiles. Currently finds utility on cellulosic and synthetic textiles, leather and wood applications. Also is used in denim company to reproduce aging effect.

Materials used in Re-FREAM

It’s possible to get different design effects depends on the material features. Designs, cuts or bas relief can be obtained and the final result depend directly to the material characteristics.

Our artist Youyang Song uses the laser technology in order to design on your new materials with the aim to obtain different design effects. Elizabeth Jayot focusses in the use of laser technology in order to obtain the pieces that can use in assembling your fashion pieces.

Technology is used by these Re-FREAM Partners

Assigned Projects within Re-FREAM

- Cooking New Material (Youyang Song)

- Fragments Garments (Elisabeth Jayot)