Conductive printing technology

About the project

About the Technology

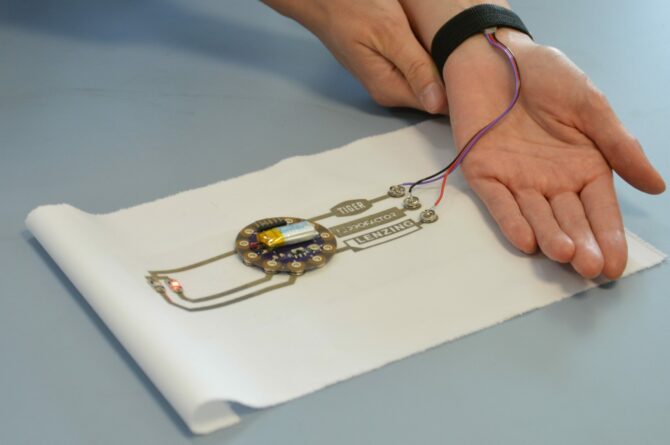

Typical printed circuit boards (PCBs) for different electronic applications are usually inflexible and not sustainable materials. In recent years, more and more technologies have been developed to apply them to even the most unusual materials such as textiles, paper, glass and wood. They suddenly become “circuit boards” and are equipped with components for electronic circuits.

Digitally printing electrically conductive materials is a new technology. Profactor is using several possibilities to apply these materials onto textiles or 3D printed objects.

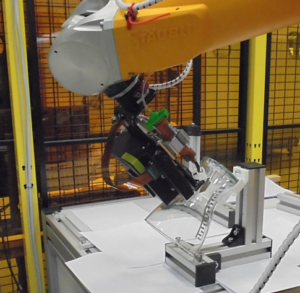

Inkjet printing is usually used in home office, however, a lot of development is done in functional inks like silver and copper inks to print with inkjet printers. There is the possibility to use inkjet print heads in bigger devices for large area, or even mounted on a 6-axis robot to print on any complex structures.

The inks for digital printing are filled with metallic nanoparticles. They form the basis for the process of additive manufacturing and are applied in the form of conductor tracks to the corresponding carrier materials in an energy-saving manner only where they are actually needed. However, the applied structures do not yet have the desired electrical properties. The printed structures only become electrically conductive through thermal post-treatment.

Dispensing is another possibility at Profactor and uses a single nozzle, compared to inkjet printing. However, for conducting paths, often no high resolution is necessary.

Usual Areas of Application

An increasing demand for alternative processes is present in the printed circuit boards (PCB) manufacturing industry. Considering photolithography as main alternative solution, inkjet printing PCBs will be: innovative, cheaper, simpler, greener, stronger and closer to the market.

Smart textiles topic is rising up. Possible fields of application of Smart Textiles are expected e.g. in the automotive, aeronautics, architecture, lighting, construction, sports, health, wellness and fashion industries.

Materials used in Re-FREAM

Silver and copper inks for inkjet printing and pastes for dispensing.

Technology is used by these Re-FREAM Partners

Profactor (Steyr, Austria)

Hubs

Hub Berlin: From analog to connected (only Profactor!)

Discover the Technology