Join our presentations at Ars Electronica 2020

From Sept 9th – 11th 2020, the 10 awarded artists of the first round of Re-FREAM and their co-creation teams give you insights in their 9 months co-creation experiences, showcasing live making-ofs of their prototype processes and sneak peeks in the labs. They show their final outcomes and explain the potential of their projects to contribute to a more responsible future of fashion.

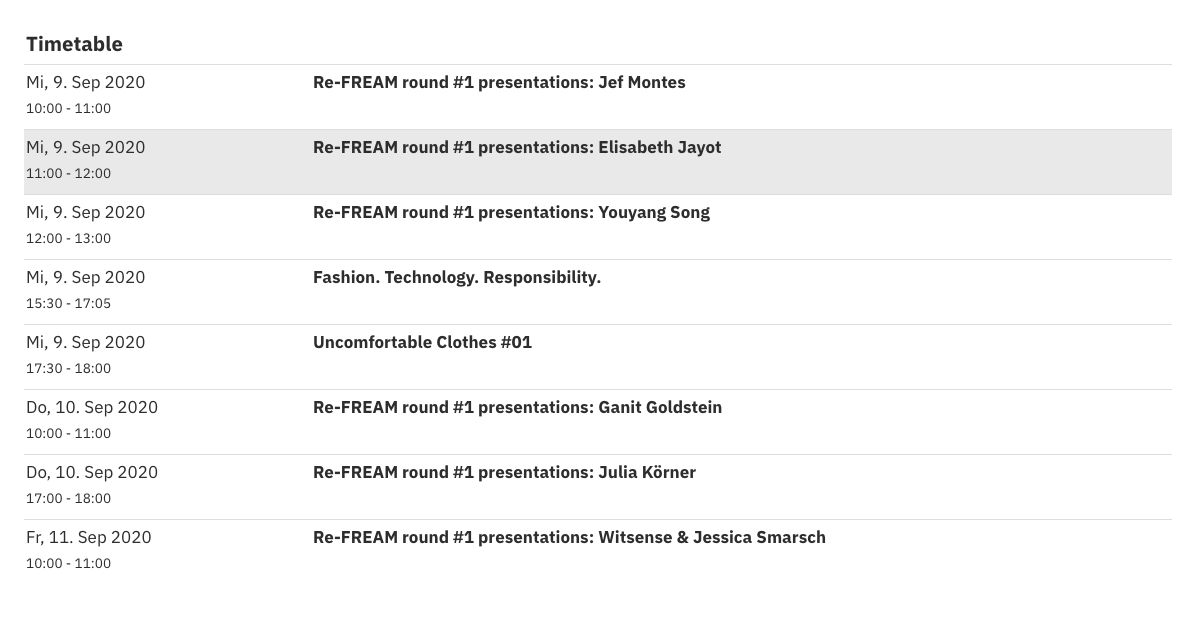

Find out more about the presentations and the schedule here: Ars Electronica Garden Linz / Valencia / Berlin – Fashion.Technology.Sustainability.

Fashion is a constantly ongoing development process, reflecting the mutable zeitgeist of a complex society; it is the art and the related design discipline that most effectively transmit the languages and messages of our contemporary culture. Fashion can, thus, also be a fundamental attitude of any human to act on the surrounding reality in order to shape it and essentially be a “change-making” action.

The research project Re-FREAM is exploring the interaction between the domains of Fashion, Design, Science, Craft and Technology, promoting a space for co-creation and research, where experimental projects will be connecting artists with scientists and technologists for better human centered and sustainable solutions.

The Re-FREAM Garden shows the results of 10 co-creation projects, illustration the potential of combining art with technology, crafting and sciences. The Re-FREAM Garden also looks at fashion from an uncomfortable perspective and opens up new spheres for sustainability and diversity with various talks and positions of artists.

Re-FREAM projects from Hub Linz - From 2D to 3D

Re-Think Manufacturing by Yokai Studio GmbH

The co-creation team around the Yokais, consistent of the Re-FREAM technologist partners Haratech, Profactor and EMPA, developed a prototype for a one-stop-shop robot based manufacturing system for fashion. The projects acts on the interface between virtuell design methods with 3D technology and new production methods and brings up the potential for urban manufacturing / local production and customized fashion.

Digital Vogue by Julia Körner

Within the Re-FREAM project “Digital Vogue – Between Organic and Synthetic Processes”, Julia Koerner (JK Design GmbH) researches 3D to 2D to 3D relationships in 3D-Printed Fashion together with the technology partners Stratasys, Haratech, Profactor and consulting partner Department of Fashion & Technology, University of Art and Design Linz. The research focuses on digitally translating patterns into algorithms and exploring multi-colour 3D printing on fabric, inspired by microscopic imagery of natural artefacts. The ultimate goal within Re-FREAM is that the design workflows can be fully automated; from design to production leading to ‘local production’ and ‘mass customisation’ and ‘rethinking urban manufacturing’.

WeAreAble by Ganit Goldstein

3D Printing & Crafts – Hybrid traditional and futuristic techniques: WeAReAble deals with the making process of customized fashion designs, based on 3D body scans and parametric codes combined with multi-color 3D printing directly on fabric. The project examines the border between future and tradition, redrawing the boundaries between hand-made and machine-made. In collaboration with: Haratech, Stratasys, Profactor , F&T department of University of Art and Design Linz.

Re-FREAM projects from Hub Berlin - From analog to connected

Alma by Giulia Tomasello

Alma is a wearable biosensor designed to monitor vaginal fluids. We strive to support and educate women* about their intimate health through technology. Our team of designers, anthropologists, scientists and engineers has co-developed with our industrial partners, Fraunhofer IZM and Empa, a new type of underwear capable of measuring vaginal fluid pH. Quantifying vaginal chemistry is an important step to close the medical gender gap and raise awareness about the female body. Our entire design process was driven by the data and insights from the Alma meets Flora survey and co-design workshops.

Lovewear by Witsense

Lovewear is a smart underwear that helps people of all abilities to self-explore and enhance their own intimacy and sexuality. Witsense wants to empower the wearer through a tactile experience achieved by soft robotics with inflatable inserts embedded in the underwear, triggered by the interaction with a connected ‘console’ pillow. The wearer can hug, cuddle, caress, press this interface as a surrogate for human contact or just explore its surface as he would explore his own body, facilitating gestures.

Connextyle: Techstyle for Rehabilitation by Jessica Smarsch

The co-creation research performed by Jessica Smarsch and Fraunhofer IZM partner Christian Dils focused on the integration of textile-based sensors (TexPCBs) into clothing for the functional purpose of gathering EMG data for stroke rehabilitation. Sensitive considerations were also made in the design of the garment to enhance the wearer’s experience with the system. Many external partners were also involved in the research, which culminated in a 2-day Stakeholder Workshop, facilitated by Fraunhofer IZM partners Max Marwede and Robin Hoske. Through guided activities, participants identified and discussed important issues related to this medical device development.

Re-FREAM projects from Hub Valencia - From linear to sustainable circular systems

Fragments Garments by Elisabeth Jayot

The Fragments Garments circular fashion supply chain aims at inverting the current fast fashion paradigm. To fight the environmental damages created by cheap clothing produced at a fast pace in low-wage countries, we propose to relocate within small urban manufacturing units akin to Fablabs, the production of garments, – moreover designed seamless and modular -, based on a worldwide digital pattern trade. This project adds a 4th dimension to the classic Reduce, Repair, Recycle concept by involving the consumer who can easily dismantle and transform clothes according to changing trends, needs or sizes, thus leading to a longer life-span.

Cooking New Materials by Youyang Song

Cooking new materials is an independently developed technique which aims to process biowastes into a soft but yet robust leather-like material. Banana and orange peel or soy-milk are combined with a natural binding agent as the substrate. The resulting composite is fully biodegradable and can be easily reused after the re-cooking process. It is a 100% biodegradable, zero waste natural product. Moreover, the bio-material provides similar toughness, durability and water resistance as normal leather material.

LEBIU by Fabio Molinas

Marinero by Jef Montes

Inspired by the contrast of the sea and plastic pollution, Marinero is the first project of Studio Adaptive Skins. The focus of Marinero is to create an architectural blueprint that transforms organically over the course of time due to different meteorological conditions.

Re-FREAM is a pillar of the STARTS Programme (Science + Technology + Arts), an initiative of the European Commission under the Horizon 2020 research and innovation programme.