3D Printing – PolyJet

About the project

About the Technology

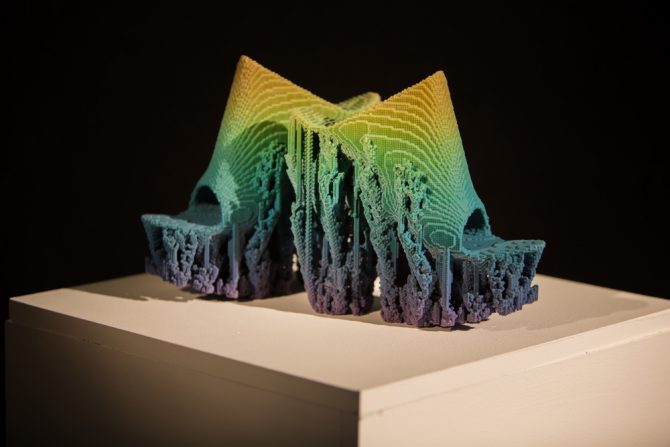

Polyjet printing is a fantastic 3D printing technique. Based on inkjet printing, PolyJet allows to generate actual multi-material objects with high accuracy around 0.02 mm which can produce thin walls and complex geometries. The materials are deposited in liquid tiny drops and then hardened layer-by-layer with UV light. Up to six individual UV-curable so called digital materials can be printed at once. Grading between the different material drops is a key feature of Polyjet. Furthermore, this technique is capable to fine tune mechanical properties at the “voxel” (volume pixel) level.

- More information about the technology: PolyJet Technology

- Find more inspiration here: 3D printed Art and Design World

Usual Areas of Application

With this young technology it is possible to achieve complex shapes, intricate details and delicate features. They can be used for accurate molds, jigs, fixtures and other industrial manufacturing tools or detailed prototypes in small lot sizes on demand.

Materials used in Re-FREAM

Usual standard materials show moderate long term stability and semi good biocompatible to skin after processing with intensive UV light. New generation materials in development bear the potential for higher durability and skin compatibility.

At Profactor processing and new materials can be investigated with 2 different material types, including conductive material from silver (within Hub Berlin)

At Stratasys, a CMYK (cyan-magenta-yellow-black)-based color palette enables fully multicolored objects. In addition, the objects can possess flexible and stiff elements, generated within one printing job.

Technology is used by these Re-FREAM Partners

- Stratasys (Rehovot, Israel)

- Profactor (Steyr, Austria)

Hubs

- Hub Linz: From 2D to 3D

- Hub Valencia: From linear to sustainable circular systems (only Profactor!)

- Hub Berlin: From analog to connected (only Profactor!)

ASSIGNED PROJECTS WITHIN RE-FREAM

- Digital Vogue – Between Synthetic and Organic Processes (Julia Körner)

- WeAreAble (Ganit Goldstein)